Simple, flexible, automated systems designed to optimize your tuna fish processing line

JBT, for Tuna Processing Lines Done Right

It’s a lot of effort to transform a live fish into a trendy ahi steak or lunch-staple tuna salad. With all the prep work and then cooking and packaging steps — you’re probably also looking at a lengthy and complex process as well.

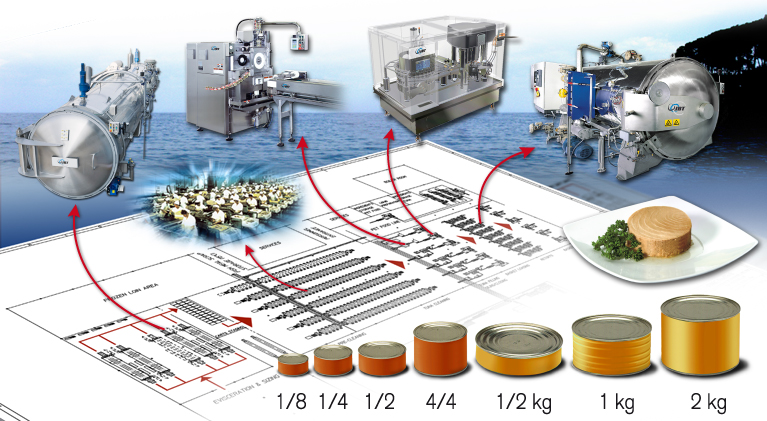

This needn’t be an insurmountable challenge for you, though. JBT has everything you need for processing tuna. For example, our massive portfolio includes products for:

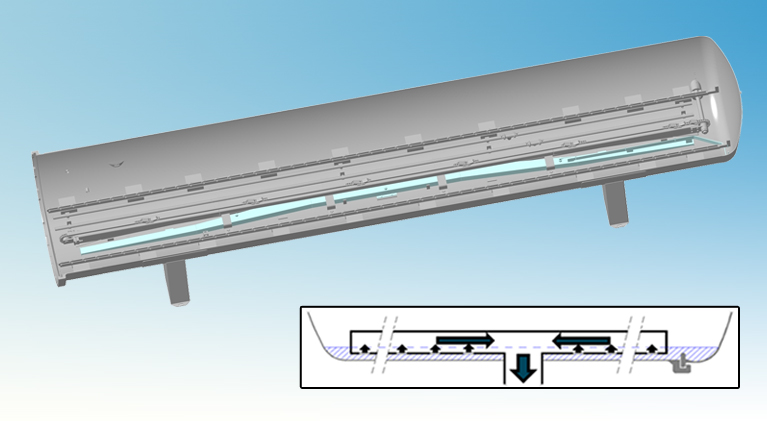

- Precooking and cooling tuna under vacuum

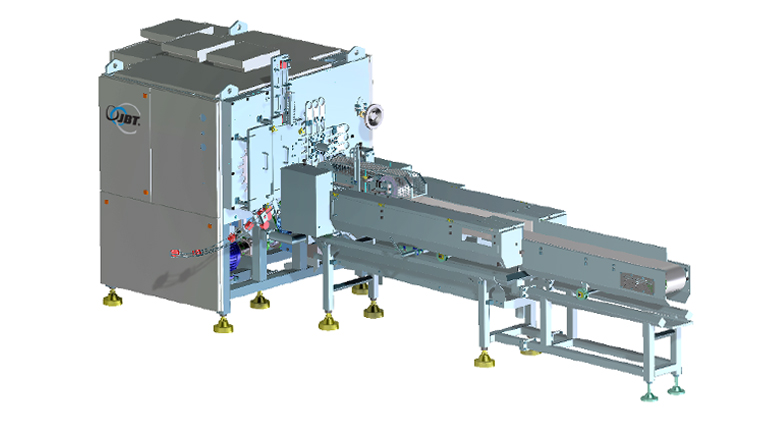

- Loin feeding

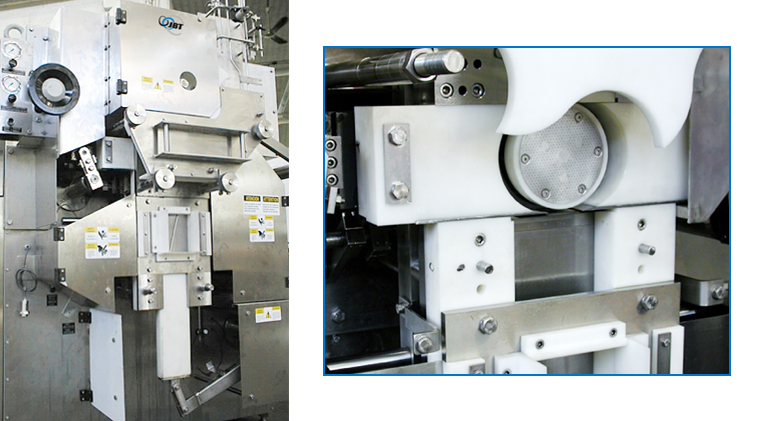

- Can filling and seaming

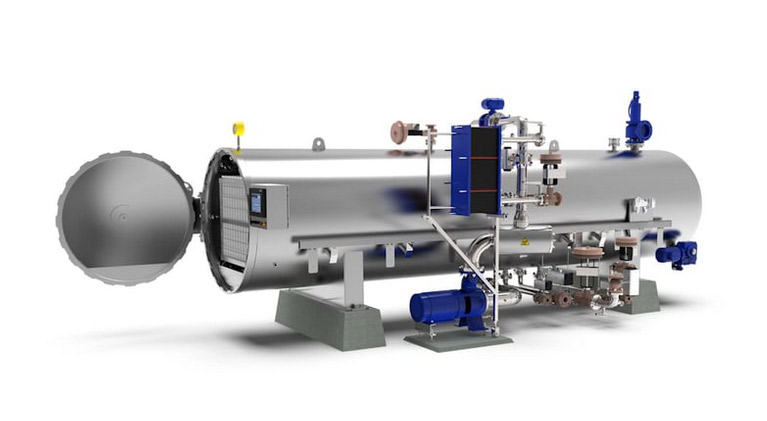

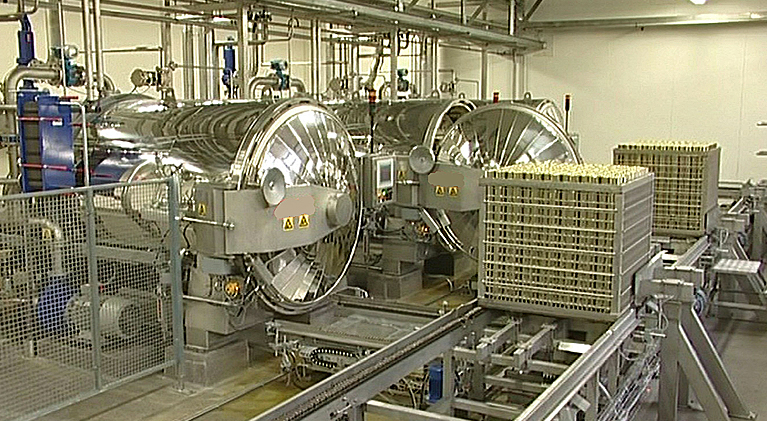

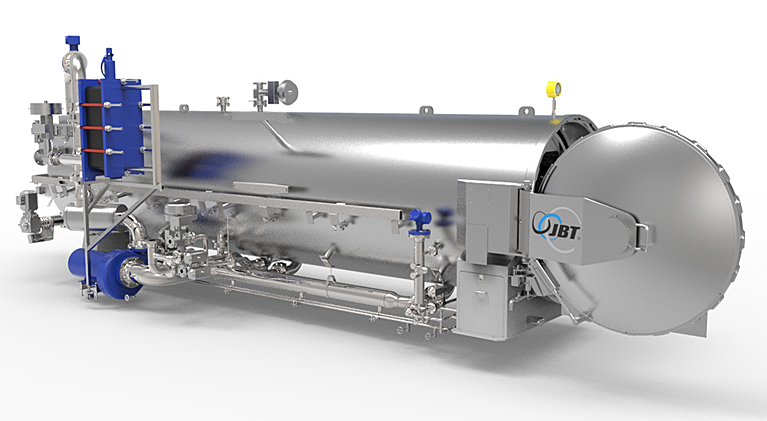

- Fully-automated batch retort systems (ABRS)

Our cutting-edge equipment makes it possible to retain the taste, texture, and appearance of raw and processed tuna. And, it does all that while also locking in freshness and nutrition!

Even better, JBT offers TunaCAL™ — our state-of-the-art yield monitoring and process control system — and consulting services. It’s easy to see how you can design a bespoke solution that enables you to achieve peak performance in your tuna processing plant.

Better Food Production from Smarter Engineering

JBT has been a leading supplier of tuna processing solutions for over 40 years. We’ve maintained our coveted edge through top-tier in-house engineering and R&D coupled with the cooperation of leading tuna processors.

This combination of skill, experience, and collaboration makes it possible for JBT to thoughtfully and intelligently design superior systems. Functionality that boosts productivity, increases equipment longevity, preserves value, and more is purposefully incorporated into each and every product.

What’s this mean for you, off the schematic and on your plant floor?

- Construction that leverages the best available techniques and materials

- Compatibility with other processing machinery

- Customizability and configurability to your specs

- Less time needed for operator training and to get up and running

- Shorter system rollout period

- Longer service life

- Higher resale potential

Food Processing That’s So Simple

With the proper machine for each step — ideally assembled into a complete, high-functioning production line — you’re well positioned to prevent and resolve production challenges. Here are some of the ways, JBT facilitates your tuna processing:

- Automation of repetitive, tedious, and more dangerous tasks

- Simple, intuitive machine controls

- Minimal operator training needed

- Reduced chance of human error

- Options to tailor systems to your particular needs

We don’t just make transforming tuna easier. JBT’s tuna processing solutions can make reaching your operational targets — like product quality, productivity, and worker safety goals — simpler, too. It comes with the territory of using JBT solutions.

Reliability You Can Count On

There’s no time for downtime. Out-of-service machinery means your spoiling ingredients, your idle workers, and delayed order fulfillment. You need equipment that can withstand the harsh demands of food production.

JBT knows what’s on the line. It’s why our tuna processing equipment is solidly fabricated using the toughest materials. This attention to detail and quality is a win for you — you’ll enjoy:

- Easier and minimal maintenance

- Fewer, less frequent, and less severe operational issues

- Fewer and shorter usage interruptions due to operational issues

Features & Benefits

JBT’s poultry processing equipment is as packed with features as a can of sardines. With all this functionality, you can count on food processing that’s fast, accurate, and safe.

- Efficient — Streamlines processing to lower operating and capital costs

- Productive — Superior systems lead to faster processing, better yield, and better product quality

- Speed — Multiple filler capacities lets you adjust production rate

- Range — Able to handle all tuna species and any style/shape of container (e.g., can, glass, pouch) for maximum adaptability

- Economical — Can be used to cost-effectively produce frozen loins

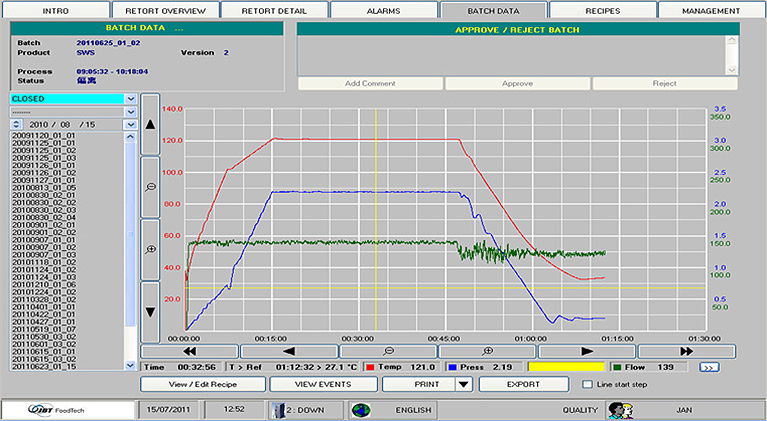

- Optimized — TunaCAL™ software perfects heat transfer profile to improve the cooking/cooling cycle

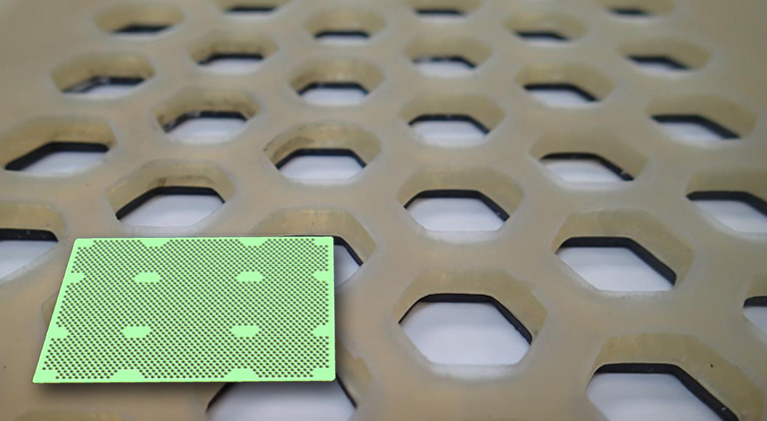

- Precision — High filling accuracy results in major cost savings

- Sterile — Uniform temperature inside the retort provides efficient, fast, and homogeneous sterilization process

- Automated — Controlled process reduces potential for human error and boosts efficiency

- Integrated — Compatibility with other equipment and operational system optimizes high-speed, flexible production

- Support — Global support staff available 24/7, year round

Have questions about these features — or how they can benefit your operations? Contact us today.

Related Products

Comprehensive FoodTech Solutions

JBT features all the high-quality equipment you require to manufacture an array of food creations. Because preparation methods vary from product to product, we carry a complete selection of machinery that includes:

- Choppers, Cutters & Emulsifiers

- Fresh Produce Technologies

- Fillers

- Pasteurizers & Sterilizers

- High-Pressure Processors

- Freezers & Chillers

- Tray Sealers

- Product Labelers

Plus, JBT has the washers, conveyors, and packagers you need for a truly comprehensive solution.

It won’t take long for you to realize that, by choosing JBT, you’re getting flexibility, transparency, and the lowest-hassle experience possible.

Your Whole Production Line In One Shot

Whether you need two or 20 machines, JBT can outfit your production line. Our extensive product offerings include one or more options for each task at hand.

With the quality and variety of food processing equipment we offer, you’re able to:

- Conveniently source equipment from a single supplier

- Customize your production line to fit your needs

- Mix and match brands to get exactly what you want

- Easily replace individual components of your current processing line

- Respond to changes with greater agility

- Scale your production with greater ease

Rest assured, JBT can set you up with the correct machinery to get every job done right.

JBT, Your Partner in FoodTech

With JBT on your side, there’s no need to keep looking for end-to-end tuna processing solutions.

A Better Approach

Making a sale and moving on isn’t how JBT does business. We work hard to build a productive, long-term relationship with you. This way, JBT can serve you more mindfully and holistically today and tomorrow.

R&D Hubs

This is a special benefit of working with JBT. More than a mere test kitchen or lab, our Research & Technology Centers let you try out machines and production line set-ups, hone your recipes and techniques, and access technical expertise and data.

Our Experts Are Here For You

With well over 100 years’ knowledge and experience, JBT’s got a skilled team ready to be your go-to FoodTech resource. We provide above-and-beyond support because we know running a food processing enterprise can be complex. Often, it’s this extra little bit of help that enables your business to thrive. So, don’t hesitate to contact us with any questions you might have.