JBT’s MEPSCO UltraCAT Injector offers superior flexibility and increased yield while reducing downtime and unnecessary costs.

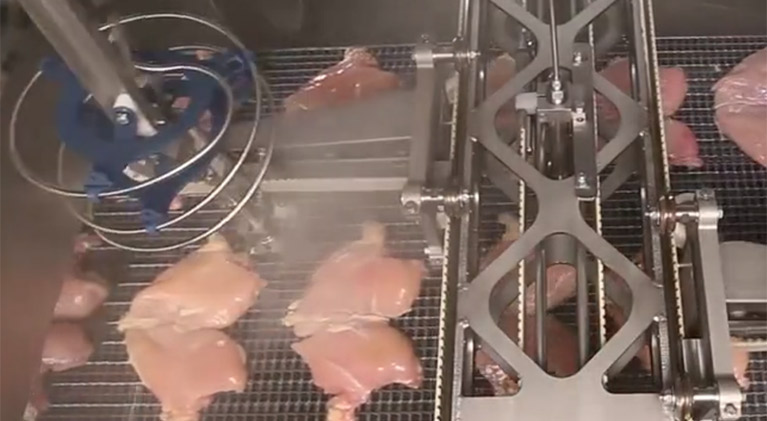

When it comes to injection in the meat processing industry, consistency is key. That’s why JBT has developed a high-tech, customizable, and accurate commercial meat injector that offers the lowest total cost of ownership on the market. With a wide variety of configurations and reliable product uniformity, the MEPSCO UltraCAT Injector is the ideal machine for processors in the poultry, meat, and seafood industries.

JBT has been supplying advanced FoodTech solutions for over a century. Our commitment to helping our customers develop a superior end product, while significantly improving overall system efficiency, has led to some of the most revolutionary advancements in food-processing technology. The MEPSCO UltraCAT Injector simplifies the process of creating high-quality, tender, and delicious meat products by prioritizing key features that give you a competitive edge without sacrificing your bottom line.

Highly accurate distribution capabilities, a user-friendly interface, maximum processing flexibility, and easier-than-ever maintenance requirements help to increase your throughput and elevate the efficiency of your entire operation without costly repairs and unnecessary downtime.

Features & Benefits

JBT’s MEPSCO UltraCAT (378 or 488) Injector is designed with cost-effectiveness, precision, safety, and efficiency in mind. Built to last and deliver the lowest total cost of ownership on the market, this injector can increase throughput and yield with minimal maintenance and cleaning requirements.

Here’s a look at what the UltraCAT (378 or 488) Injector offers:

- Accuracy – Built to inject and marinate poultry, meat, and seafood products quickly, without sacrificing precision, the UltraCAT (378 or 488) injector distributes moisture uniformly at production rates up to 35,000 pounds per hour.

- Minimal maintenance requirements – With stainless-steel surfaces and a supremely efficient filtration system featuring a self-cleaning drum filter that can eliminate 95% of solids, the UltraCAT injector couldn’t be simpler to clean. Dual pressure filters also work to significantly reduce any solids before going into the needles.

- Customizability – With multiple needle sizes to choose from, an optional 1-way (down) or 2-way full-flow (up and down) brine valve, and a fully adjustable injector speed, this MEPSCO UltraCAT injector can be optimized for any production application.

- Efficiency – With injector speeds up to 55 strokes per minute, quick-change needle modules, an impressive 60-gallon brine holding tank, and up to 85% injection range from a single pass (depending on the product), you can save time and boost productivity.

- Ease-of-operation – Designed with reliability, user safety, and convenience in mind, the injector’s programmable touch screen is simple and intuitive to use.

Safe Operation, Hygienic Design

We know that protecting the safety of your employees and your consumer base is of the utmost importance. The UltraCAT offers easy cleanability with an innovative, sanitary design that boasts stainless steel surfaces with an efficient filtration system. A self-cleaning drum filter and dual pressure filters help to eliminate more than 95% of solids, protecting the health and safety of your consumers and workers. A programmable touch screen with a highly-intuitive control system also allows the user to operate the UltraCAT safely and effectively without the need for extensive training.

FAQs

What needles can be used with the UltraCAT (378 or 488) Injector?

You can choose the right model to meet your specific production applications, with needle configurations of 378 or 488. The UltraCAT is compatible with special alloy stainless-steel standard needles or optional tenderizer needles. Both needle types are available in sizes .118” (3 mm), .158” (4 mm), and .188” (5 mm) to provide maximum flexibility.

What are the maintenance requirements?

The UltraCAT is designed to maximize uptime and reduce the need for maintenance to deliver the lowest cost of ownership possible. With stainless-steel surfaces and a self-cleaning drum filter, the machine is simple and easy to clean. When maintenance or replacement parts are required, JBT experts are available around the clock to provide you with recommendations, insights, support, and service.

What types of products can be processed using the UltraCAT Injector?

The UltraCAT is perfectly suited to accommodate the marination and injection of a wide variety of bone-in and boneless meat products. Whether you’re processing pork bellies, poultry, or seafood, you’re guaranteed to find the right configuration to suit your specific market and preferences. With such an expansive range of customizable features, your output will not only taste better, but it will also display superior uniformity and overall quality.

JBT – At the Cutting-Edge of FoodTech

At JBT, we’re known for our dedication to relentless innovation and our unwavering commitment to our partner’s ongoing success. Our mission is to consistently design and produce the most advanced food-processing equipment on the market and provide the highest quality customer service and support possible.

When you work with JBT, you’ll get the opportunity to:

- Choose from our extensive catalog of premium equipment

- Customize production designs and approaches

- Integrate equipment from a variety of different brands to optimize your production lines

- Easily access replacement parts and equipment components to keep your operations running smoothly

You can also take advantage of personalized services, which include upgrade kits, parts, service and maintenance, and specialized training.

Targeted Solutions for Diverse Markets

You’re more than just another sale to us. We value the long-term partnerships we build with our customers. JBT is privileged to work with a broad range of companies that serve a variety of domestic and global markets. We’re grateful for the diversity and broad perspectives our partners offer. We specialize in a wide variety of markets, including:

- Bread and pasta

- Coffee and tea

- Fruits and nuts

- Non-foods

- Pet foods

- Pharmaceuticals

- Poultry, meat, and seafood

- Ready meals

- Sandwiches and snack foods

- Vegetables and potatoes

Join Us at Our High-Tech Research Facilities All Over the World

Our commitment to collaborative research and development has led to some of the most innovative and revolutionary technology in food processing. We want to make sure our partners are involved in the process. As a JBT partner, you’ll have the opportunity to visit our global Research and Technology Centers to work side-by-side with our incredible specialists. You’ll get to test equipment, perfect your recipes, try out new setups and configurations, and get an up-close-and-personal look at our operation.

Get Unmatched Support From True Experts in FoodTech

At JBT, we’ve worked throughout our long history to not just offer high-tech food-processing solutions, but also to develop reliable expertise and gain real-world experience in a wide variety of diverse markets. With the knowledge we’ve amassed over the years, we have the tools to offer you comprehensive support no matter the challenges you face.

Whether you need quick and efficient maintenance service, industry insight from experts in the field, or are looking for new ways to optimize your production lines, our team of experts is available 24/7 to offer you the customer support you need to build your business and reach the top of your industry.

Contact us anytime to learn more about our offerings and become a member of the JBT family!