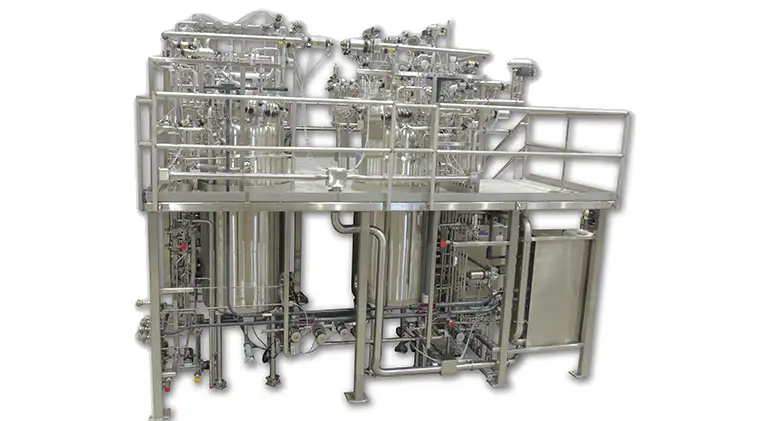

Pharmaceutical Sanitary Process Systems

Accelerating your production with state-of-the-art, hygienic automated solutions to meet the wide-ranging needs of pharmaceutical and biotech businesses

JBT Pharmaceutical Process Equipment – The Best of the Best

Your mission may be something akin to helping to “heal sickness” and “preserve wellness.” That’s an extraordinarily important endeavor! Potentially billions of people around the world are depending upon you and your products — medicines, supplements, and more.

You don’t want to let anyone down. That could literally translate into sick patients not getting the treatments they need.

The best option? Establish a rock-solid manufacturing ecosystem — one that you know will consistently enable you to produce your pharmaceutical or biotech goods.

Doing so can be a daunting effort. However, this is one of the many areas in which JBT shines. We specialize in process equipment and ancillary services required to create safe, compliant pharmaceutical products and production facilities.

To give you an idea, JBT makes pharmaceutical-grade processing equipment such as:

- Process vessels and modules

- Clean-in-Place (CIP) systems

- High-purity piping

- Storage tanks

- Mix systems

- Media preparation and hold

- Buffer Preparation and hold

- Autoclaves/Retort Sterilizers

- HTST/UHT

- Harvest vessels

- Small molecule formulation skids

- Filtration skids

- WFI hold and distribution

- Viral inactivation

- Transfer panels and arrays

Time-To-Market

It’s imperative that you turn out mass quantities of safe pharmaceutical products at a steady rate. Literally, people’s lives are hanging in the balance.

JBT fully comprehends the stakes. This is why we’ve worked so hard to design and build the best possible pharmaceutical solutions.

Engineered in – from initial design to finished machine – are smart features and functionality that boost efficiency, equipment longevity, and more. The results – a jackpot for you – include:

- Construction using the best processes and materials meeting BPE and other global standards

- Integration of Unit Operations at the factory, reducing field install and testing

- Full factory testing meeting ASTM standards to reduce on-site commissioning

- Parallel Design/Build activities resulting in reduced delivery schedules

We design our own skids, build our own vessels, perform our own automation, and field install and commission our own equipment. In the end, we have control of the quality and schedule of our solutions.

Bioprocessing Made Easy

Since there’s a machine for every task, you can assemble equipment into a complete production line that’s perfectly tuned to your requirements. It’s not difficult to see how creating purpose-built sanitary process equipment solutions for your pharmaceutical product can prevent or resolve many of your challenges.

A tailored-to-your-business production line, streamlines and simplifies operations through:

- Process automation

- Minimizing the training needed to operate machinery

- Reducing opportunities for human error

- Affording you countless options to address your particular needs

Another way JBT’s pharmaceuticals solutions make the business of bioprocessing easier? With personalized, appropriate manufacturing systems, hitting your operational targets – like improving productivity, reducing downtime, and so on — comes more naturally. It’s part of the bargain when using JBT equipment.

Built-In Reliability

With your production line, there’s no room for error or downtime. When processing equipment isn’t operating at peak levels, costly problems can arise. Process equipment you can count on – all day, every day – is non-negotiable.

JBT understands all the implications of equipment failures and manufacturing delays. That’s why our pharmaceutical process equipment is made to last and perform well. It’s solidly constructed using the most durable materials.

Because of this attention to detail and quality, you’ll experience:

- Less, easier, and cheaper maintenance

- Fewer and milder operational issues

- Fewer and briefer stoppages due to operational issues

Features & Benefits

JBT’s pharmaceutical processing equipment is full of desirable features and functionality. This makes for production that’s consistently as quick, precise, and secure as possible.

- Expertise – Extensive track record of helping world’s leading biotech companies establish robust, successful operations

- Bespoke – Customized solutions for your specific product and facility

- Savings – Proper equipment coupled with expert consulting and services can lead to lower implementation and ongoing costs

- Safe – Checks and balances through every phase of installation and operation ensure product quality and safety

- Compliant – Knowledgeable team and reliable equipment assure FDA regulations are met

- Sanitary – Hygienic design and construction for enhanced clean-ability

- Adaptability – Able to process a variety of products

- Extensible – Can add on secondary processing equipment for sterilization, aseptic filling, concentration/evaporation

- Innovation – Extensive testing capabilities to help facilitate product development

- Support – Global support staff to help as needed

If you have any questions about these features – or how they benefit your operations – contact our team today.

Comprehensive Technical Solutions for Manufacturing

JBT offers an array of high-quality equipment and services to handle the many processes and intricacies of pharmaceutical production.

JBT Pharmaceutical Equipment for All of Your Manufacturing Automation Needs

Whether you’re looking to augment your set-up with a single machine or build out a whole new manufacturing facility, JBT has everything you need. Our portfolio of products – which is vast – is sure to have several options for each step of your process.

Knowing that each product requires a unique mix of inputs or method of preparation, JBT carries machinery for applications like:

- Cleaning-in-place

- Tray sealing

- Aseptic filling

- In-container sterilization

- Filling and closing packaging

With the breadth of heavy-duty manufacturing equipment from JBT (not to mention our upgrade kits, parts, detergents, and lubricants), it’s no wonder you’ll be able to:

- Conveniently do one-stop shopping for equipment

- Create a bespoke production line to best suit your needs

- Mix and match brands so you get exactly what you want

- Easily replace individual components of your existing production line

- Respond more agilely to product, process, or regulatory changes

- More seamlessly scale your production

- Realize time and cost savings

Bottom line: JBT can supply you with the proper equipment to get every job done correctly. And, we make assembling your production line as straightforward and hassle-free as possible.

CONTACT US

We’re here to help every step of the way.

Sales Questions

Get Support

Related Resources

- Brochure A&B Pharmaceutical – EN

- Brochure Fermenters and Bioreactor – EN

More Markets

- Baby Food

- Bakery & Confectionery

- Bread & Pasta

- Coffee & Tea

- Dairy & Dairy Alternatives

- Fish & Seafood

- Fresh Cut Produce

- Fruits & Nuts

- Non-Food

- Oils, Soups, Sauces, Seasonings & Dressings

- Pet Food

- Pharmaceutical Sanitary Process Systems

- Plant-Based Beverages

- Plant-Based Protein

- Juices & Beverages

- Poultry & Meat

- Ready Meals

- Sweet Spreads, Honey & Syrups

- Vegetables & Potatoes