JBT and Marel: United to transform the future of food

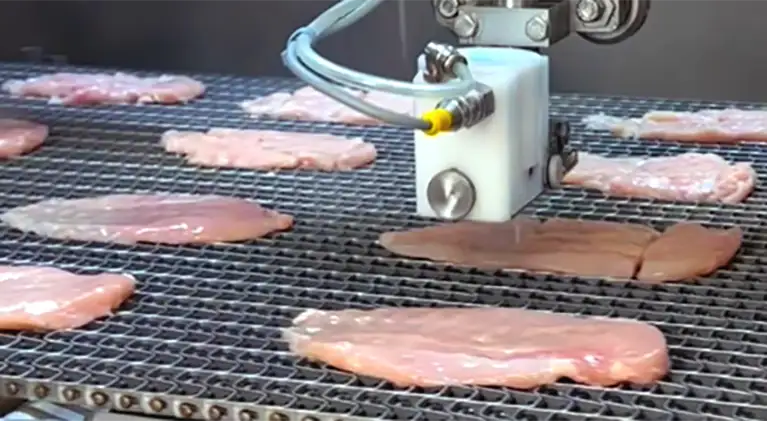

Get up to 25% more yield and maximize utilization, throughput, and flexibility with the new intelligent JBT DSI™ 812 Waterjet portioner. Its compact design suits many different production capacities and fits right into your line. The proven waterjet technology already gives a competitive edge to numerous poultry producers in Europe and worldwide.

CUTTING-EDGE YIELD

Get your profitability into better shape

Maximize yield and profits by finding the optimal cut strategies for each piece of raw product with unique laser scanning technology and intelligent algorithms that locate fat and determine shape, thickness, and weight.

CUTTING-EDGE FLEXIBILITY

Discover the pattern of successful portioning

Quickly generate complex tailor- made

cut shapes in any form in one pass while still hitting weight and dimension targets with the DSI 812 high-pressure waterjet and the DSI Q-LINK™ Portioning Software.

CUTTING-EDGE EFFICIENCY

Fuel your portioner with jet power

Create a higher yield, maximize throughput, and improve product quality by switching from hand or semi-automated cutting to a fully automated and intelligent inline waterjet portioner with a footprint comparable to a blade cutter.

Experience the DSI 812 in action!

Are you curious how the JBT DSI 812 can make your portioning process more efficient, intelligent, and profitable? Book a demonstration at our Food Tech Center in Helsingborg, Sweden, with our DSI portioning experts. Or, book an on-site demonstration in your own facility and production environment.

PRODUCING FOR QSR?

Maximize your portioning precision and meet every customer’s demand

The JBT DSI 812 gives you total control over your poultry portioning, enabling you to reach new QSR customers with high weight and dimensional specifications requirements and maximize yield and utilization.

CUTTING BY HAND?

Take your portioning inline and boost throughput

Boost your throughput, remove the risk of human error, and utilize your workers in other areas with the fully automated and intelligent JBT DSI 812 waterjet portioner.

USING A BLADE CUTTER?

Increase your yield by up to 25% with a flexible portioner

Quickly generate complex tailor-made cut shapes in any form in one pass while still hitting weight and dimension targets with the DSI 812 high-pressure waterjet and the DSI Q-LINK™ Portioning Software.

MAKE IT SUSTAINABLE

Save resources – and the planet

The JBT DSI 812 makes better use of the world’s precious resources by reducing food waste through maximzed yield and utilization of product while saving energy and optimizing water usage, making your process more sustainable.

Interested in growing your portioning business?

Learn more about our products and find out how we can help you every step of the way.

Get a Sneek Peak of our New DSI 812

25% more yield

Get up to 25% more yield with the JBT DSI 812 waterjet portioner.

50+ unique patterns

JBT DSI 812 has more than 50 templates for different portioning patterns.

30% more capacity

Unique high-speed portioning with the JBT DSI 812 Jet-Blocker.

ABOUT JBT

Empower Your Poultry Business With JBT

At JBT, we are committed to your success, and we aim to be your partner in the long run. For us, delivering a scalable state-of-the-art food processing solution is not enough. We want to work with you to empower your poultry business and share our knowledge, helping you optimize your operational performance and maximize your uptime with predictive maintenance while reducing your total cost of ownership.

Being a full-service partner means we can supply you with all the solutions and knowledge you need to empower your poultry business. It also means that we offer flexible solutions that are easily scalable when your business is growing and that we guide you in finding the best set-up for your needs. But most of all, it means being committed to securing that your operation is as efficient, stable, and optimized as possible – today and in the future. We’re with you, right down the line.™

JBT Food Technology Center (FTC) for Protein in Helsingborg, Sweden. For over 40 years JBT’s Food Technology Centers have been a popular destination for hundreds of food processors throughout the world.