Grow your business, minimize your footprint

Setting up and maintaining a sustainable production line is essential both for your economy and our planet. Producing food with higher efficiency using sustainable equipment can create more yield with less energy consumption and food waste. But to do that, you need injectors, portioners, cookers, chillers, and freezers that are energy, water, and material efficient, constructed and manufactured to obtain a minimal carbon footprint. With packaging solutions and high-pressure processing that extends shelf-life without preservatives, you can reduce food waste and maintain a clean label. If you aim to become more sustainable, JBT is your perfect partner. Our mission is to make better use of the world’s precious resources by providing solutions that substantially enhance our customers’ success.

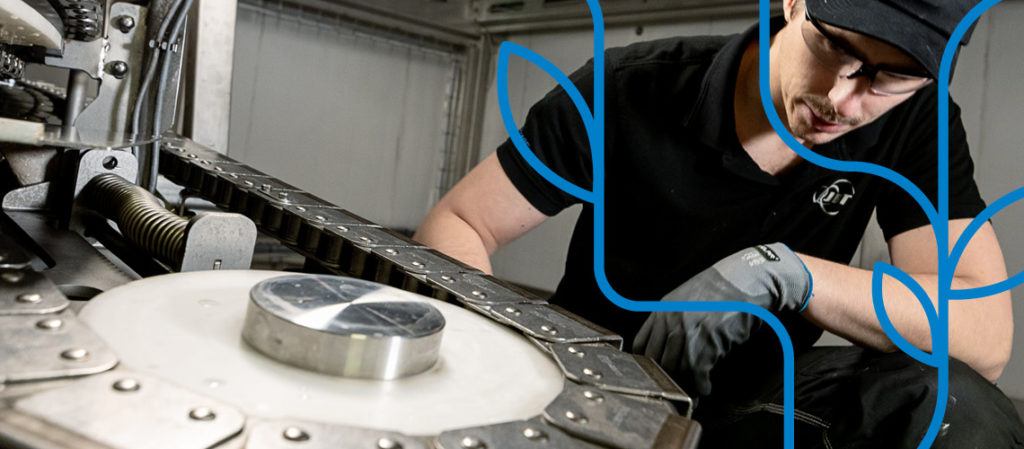

A sustainable production line for food processing starts and ends with design, and there are many aspects to consider. The equipment should reduce food waste and have low energy consumption and water usage while ensuring high food security. The construction of the equipment is also essential; for example, the smaller it is, the less material and resources it has consumed when manufactured. At JBT, we have specialists focusing on reducing the use of materials.

Minimizing food waste

The use of our freezers plays a significant role in reducing food waste. By freezing food, it stays fresh longer and provides more time for the consumer to enjoy it before it reaches its expiration date and needs to be thrown out. We believe it is essential to continue innovating and deploying food and beverage preservation solutions. It has been proven that frozen foods, ambient shelf-stable foods, and extended shelf-life refrigerated foods help reduce waste and create a more secure global food system.

One example of how we innovate to create better preservation solutions is our freezers. “Over freezing” causes dehydration that will affect the frozen product, making it shriveled, dry, and tough. To optimally freeze or chill any one particular food product, there are millions of potential configurations and operating parameters that you must accurately specify. To manage this, we have developed GYRoCAP, a software that can optimize the freezing process. That way, we can help our customers to get the highest output at the lowest cost for the desired food product, reducing the risk for food waste.

Our innovative Avure HPP technology makes it possible to extend shelf life without infusing the product with chemicals, additives, or preservatives. With HPP, shelf life can be extended with factors of three for juice and three to ten for meats and still preserve the food’s natural nutrition, freshness, texture, and flavor.

Another area that can greatly impact reducing food waste and increasing yield is the cutting and portioning of the product. The goal is to use every part of the incoming product so nothing goes to waste. JBT’s intelligent DSI waterjet cutting and portioning system scans every incoming product and automatically determines the optimum cutting paths to produce the desired outcome. It also evaluates how best to use any remaining product area for additional products like cubes, strips, nuggets, and more. Besides reducing food waste, it also consistently improves product yield and increases productivity.

JBT continues to create environmentally-minded solutions around packaging. Innovative and efficient Tipper Tie equipment bags, nets, and clips a variety of packages. Chub packaging, for example, generates ten times less packaging waste than other containers making it one of the most environmentally friendly options in packaging (Chacon, Trovagunta, Scouse). JBT Tipper Tie clipping machines, whether manual, semi-automatic or fully automatic, make it easy for companies large and small to choose an environmentally sustainable packaging solution for their products.

Our tray sealing equipment from Proseal is an ideal packaging solution to minimize food waste, extend product shelf-life and preserve quality while reducing packaging materials by up to 45% compared to other packaging formats. Proseal’s top-sealed food tray is another perfect example of food waste reduction. It provides suitable protection on the journey from factory to retailer to home. For example, grapes sold in sealed trays rather than loose bunches can typically reduce waste in stores by over 20%. One half of the pack can be separated from the other with special snap-packs. One part can be opened and consumed, while the other half remains sealed, with the product still protected and its shelf-life extension method intact, ready for later consumption.

Reducing energy consumption

We constantly develop our equipment to make them more and more energy efficient. For example, we have a heat recovery system as an upgrade to some of our sterilizer equipment that can reduce steam usage by up to 40%, decreasing the overall thermal load of the cooling tower, resulting in substantial energy savings.

The self-stacking construction in JBT Frigoscandia spiral freezers is extremely energy efficient. By offering no tension instead of low tension, it only needs a 5,5 KW motor which is half of what a traditional drum freezer requires, reducing energy consumption by almost 30%. The Frigoscandia Low Volume System (LVS) is up to 20% more efficient than the traditional pumped refrigerator system, and it requires 15% less energy and 50% less refrigerant charge than conventional systems.

Reducing water consumption

Water is becoming a limited natural resource, and in many parts of the world, our customers now must pay a tariff on their wastewater based on how much they produce and how clean it is. So, to be sustainable, a production line must be as efficient as possible when it comes to water usage and wastewater management. Our water reuse equipment is becoming increasingly valuable and can help conserve significant amounts of water for our food processing customers. For example, a poultry processing line working through 1,200 birds per hour could save one gallon per bird processed, equating to 48 million gallons per year in total savings for just that one line of production.

Our self-stacking Frigoscandia GYRoCOMPACT Spiral Freezer consumes up to 65 % less water and requires 50% less cleaning time than a traditional drum freezer because it has no stationary parts in the belt stack.

Want to know more about how JBT can help you create a sustainable process line? Don’t miss the opportunity to meet our food processing experts and find out how we can support you.

Themes

Time to grow together with JBT