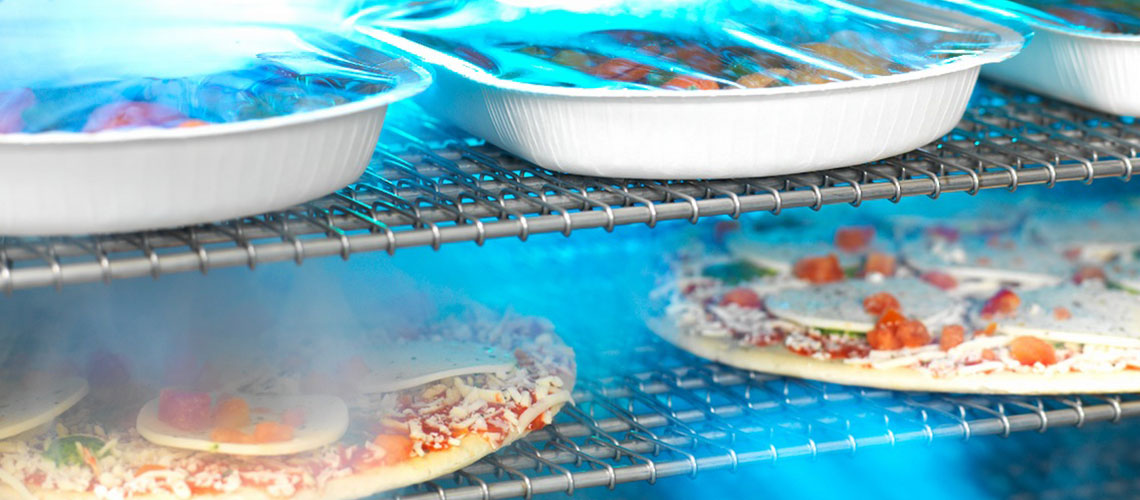

Statistics from the Plant-Based Foods Association show that frozen vegan meat keeps growing at a brisk pace. Not surprising, as frozen meals bring multiple benefits compared to fresh food: higher affordability, better retention of vitamins and minerals, and extended expiration dates. By freezing the product, we help reducing food waste and make better use of our precious resources. But freezing with good results can be a challenge. Fortunately, JBT’s brand Frigoscandia is the global leader in the art of freezing food. Here, our food experts share some valuable knowledge on how to succeed with freezing your plant-based product.

Different freezing techniques for vegan meat

Many manufacturers use nitrogen tunnels for freezing when setting up a new production line. Nitrogen can seem to be a suitable freezing medium when starting up and for small scale business. However, from a total investment perspective, nitrogen comes with a high operational cost, why it is often more reasonable to invest in a mechanical freezer. Mechanical freezing helps reduce production costs, consequently creating a more affordable plant-based product once in the grocery store. We use three main mechanical methods of freezing food: spiral, impingement and IQF (individual quick freezing) or fluidizing. Our equipment is always hygienic by design and help increase the yield and capacity of your production line without extending the footprint.

Learn more about our freezing solutions

Spiral freezing

Spiral freezing is ideal for large or thick products and heavy belt loads, such as prepared meals, warm goods, nuggets and burgers. With its compact, streamlined design, the spiral freezer can help you minimize the refrigeration footprint in your facility. Furthermore, it helps you save energy and increase the efficiency of the production line. Frigoscandia has developed the market leading products in spiral freezing, the GYRoCOMPACT series, with patented advantages such as self-stacking belts and the industry’s only self-contained freezing zone that is a 100 per cent cleanable to satisfy rigorous hygiene requirements.

Discover spiral freezing with GYRoCOMPACT freezers

Impingement technology

Apart from bread with living yeast, most food is better preserved when quickly frozen. There is a tremendous difference between freezing something at -18°C in your kitchen and putting your application in an industry freezer. The hydration, appearance, flavor and texture of the product is always affected to a certain degree depending on the speed of the process. Our freezers use impingement technology, a revolutionary solution with thousands of high-velocity air jets that blast away the boundary layer of air that holds heat around the product. The product is frozen instantly, with maintained quality. Impingement freezing is best suited for products with a high surface to mass ratio, for instance thin products like burgers, where the heat can quickly be removed from the surface.

ADVANTEC® helps you succeed with impingement freezing

Individual quick freezing

Back in the days when you bought frozen raspberries and peas, they came in a big, heavy ice block. Even though you just wanted a small quantity, you needed to defrost the whole package. In 1962, Frigoscandia made a breakthrough in individual quick freezing (IQF). Adding true fluidization made it possible to freeze any fresh fruit and vegetable as a separate entity. Today, the IQF technology is still one of the most cost-effective ways to create a fresh product that preserves its premium quality – months after the harvest. The method benefits the user experience when opening and handling your product.

Individual quick freezing can also be used for small pieces of vegan meat, e.g., for mince, balls and cubes. JBT’s FLoFREEZE is the world-leading linear freezer with IQF technology. Thanks to continuous advancement, it is possible to freeze a much greater range of products – with high capacities, complete cleanability and impressive accessibility.

Explore Frigoscandia FLoFREEZE® IQF Freezer

Glazing

Some products are more fragile than others in a frozen state. For instance, broccoli trees tend to drop their “leaves” during a shaky transport. To solve this problem, we glaze the broccoli with water before freezing it. The water stops the trees from breaking, but also capsules the small amount of fat inside the broccoli and prevents it from decaying. By glazing your product, you protect both the appearance and its nutrients while also increasing the shelf life.

Do you want to know more about freezing vegan meat?

We are eager to help you find the optimal freezing process! Please get in touch with your local sales office to find out more.

Related products

Need help developing your product?

With the world’s largest database with application tests and more than 30 years of experience in processing plant-based protein, we know how to make the most out of your product in terms of taste, yield and consistency. The food experts at our Food Technology Centers help you develop your ideas or enhance existing ones. The tests can be conducted on our testing site in person or via live video link or as on-site demonstrations with our mobile lab equipment in your facility.