Recalls are every food producer’s nightmare. Apart from potentially harming customers’ health and the financial loss from unsold products and long downtime in the production line, food safety issues might also cause severe damage to your brand’s reputation. That’s why hygiene should always be the top priority at the production facility. Since JBT started, we have acquired a deep knowledge of food safety. All of our solutions are hygienic-by-design and easy to clean and maintain. As your committed partner, we are eager to help you improve the hygiene in your food production line.

We provide food safety solutions for processes including injecting, forming, coating, cooking, frying, freezing, high pressure processing (HPP), and packaging, and food portioning.

At JBT, food safety starts at the drawing board, where we design to minimize all unnecessary surfaces and use as little material as possible to avoid dirt traps. We call it Hygiene by Design and it is especially important in food zone 1 where the equipment has direct physical contact with the products. But also, in surrounding food zones where biofilm can increase the risk for bacterial growth.

Hygienic by Design

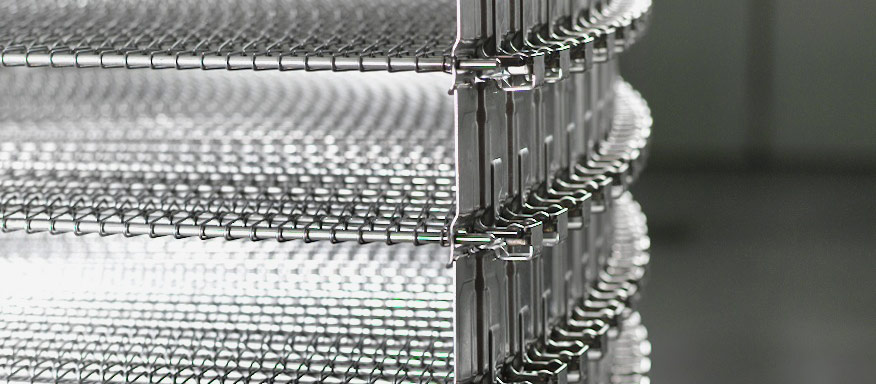

One example of Hygiene by Design is the Frigoscandia self-stacking belt that builds up a self-contained product zone reducing the structural parts, which means fewer surfaces to be cleaned, less wasted water and less detergents consumption. With the self-stacking belt design there is no stationary rail support structure that can be found in the other types of spiral freezers, which results in collected debris and is almost impossible to clean. For the toughest food productions JBT offers a unique design and innovation in the Fully Welded Enclosures (FWE), combining disinfection with hot steam sanitation. This hygienic design removes the risk of biofilm and microbiological growth in a freezer unit.

The Schröder product lines of IMAX´s stainless steel injectors for protein foods are also designed to meet the highest standards of food safety. Its external brine path is easily accessible and can be quickly removed for cleaning and inspection to ensure products are not cross-contaminated. Another important part of food safety is the ability to easily remove needles. The IMAX injectors have been designed so that all can be removed in less than 5 minutes.

Food safety without heat or preservatives

An effective way to secure food safety is the cold pasteurization technique developed by JBT Avure HPP. It leverages ultra-high pressure purified water (up to 6,000 bar / 87,000 psi – more than the deepest ocean) to inactivate bacteria – like listeria, E. coli, and salmonella. Neutralizing pathogens makes it so that packaged foods can stay fresher longer. In addition to bolstering safety and extending shelf life, HPP preserves food’s natural nutrition, freshness, texture, and flavor.

Inspection and maintenance

X-ray food inspection is a preventive technology that can help you detect contamination and foreign material in packaging and processed food to avoid recalls and hazardous bacterial outbreaks. JBT has developed a JBT X-ray Guided Waterjet Prortioning System, that are easily integrated into your production line.

Regular inspections and preventive maintenance are also important factors for safe operations. By continuously monitoring the machine’s performance, you can make sure that every application is treated correctly. Just a slight deviation in the temperature can significantly impact the product’s safety and shelf-life. JBT offers a wide range of connected solutions, that automatically monitor the performance and alarms when in need of action or troubleshooting. This also makes it possible to monitor and maintain a history of plant processing operations enabling processors to confirm critical process operations. This historical information is also available for traceability in the event of a product recall.

Cleaning

Cleaning the equipment is of course a vital part of food safety. JBT offers solutions specifically designed for fast, thorough, and economical for manual as well as CIP cleaning of your food processing equipment. Moreover, JBT has developed a series of detergents that meet the rigorous requirements of legislative and customers. Naturally, all of our products are designed to work within food production facilities. They can handle both extreme temperatures and prevent bacterial growth. In addition, we provide training in general food safety, HACCP, use of cleaning systems, and the design of equipment for sanitation.