Efficiently and accurately cutting, portioning and sorting poultry, meat, and seafood to produce portioned fillets, nuggets, chunks, strips, and fat-trimmed products

JBT, the Grade A Choice in Food Slicing & Portioning Solutions

Looking to efficiently portion chicken, beef, pork and seafood with high yields, high throughput and with maximum labor efficiency? JBT’s DSI water-jet portioners are the answer.

Globally, hundreds of our DSI portioning machines are slicing and dicing in the poultry, meat, and seafood, and pet food industries. They’re able to output a stunning variety of products, such as:

- Poultry parts, fillets, steaks, medallions, strips, nuggets and even complicated shapes

- Trimmed red meat steaks and loins

- Pork bellies and trimmed ribs

- Fish steaks, sticks, nuggets and more

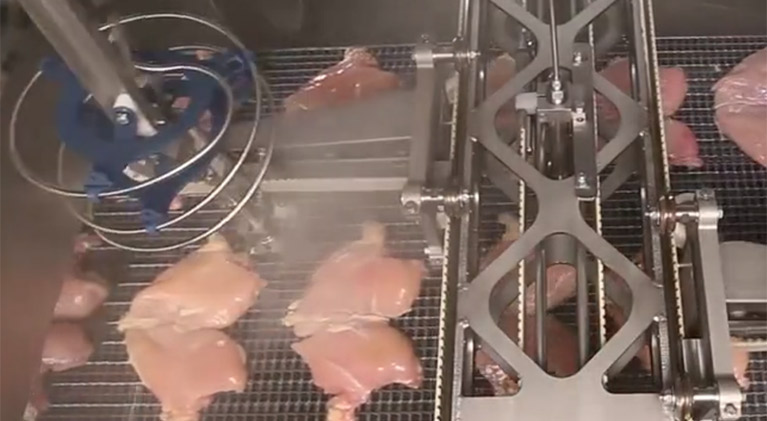

The key is computerized scanning of every piece coming into the machine, and sophisticated programming that controls a high-speed, robotic water-jet cutting head to portion, slice, strip and/or cube. Having so many options really puts you in control. With JBT’s automated meat portioning and slicing solutions, you’re able to respond to shifts in marketplace demands with speed and agility.

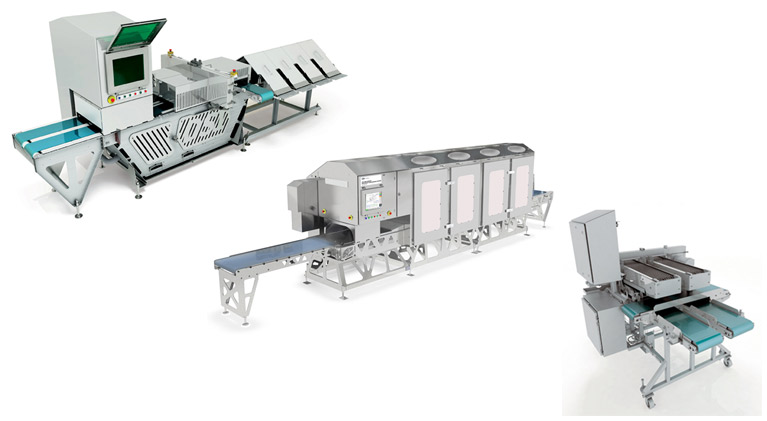

A Machine for Every Application

It’s no wonder there are so many JBT slicing solutions deployed worldwide. We’re constantly refining DSI hardware and software based on food producers’ input. The result – a comprehensive collection of meat portioning and slicing solutions easily configurable for multiple products and production needs.

Our full line of slicing, waterjet cutting, and sorting equipment includes:

- Waterjet portioners

- Horizontal slicers

- 3D portioners

- X-ray guided solutions

- Systems with multiple cutting heads for a wide rage of portioning speeds

JBT’s DSI Water Jet Portioners can be fit into an existing protein processing line, or can be delivered with other JBT equipment for an all-new high-speed line. Our experts can help you set up a processing line that portions and cuts what you need today, and is flexible to adapt to different product needs in the future.

Engineered for the Best Results

We focus on thoughtful design and manufacturing processes developed from DSI’s years of experience in the portioning industry, producing equipment that is intelligent, accurate, durable, configurable and adaptable for a wide range of protein portioning requirements.

This attention to detail also translates into:

- Construction using the latest processes and best materials

- Compatibility with other food processing equipment

- Adaptable to meet your production requirements

- Allows for less food waste

- Fast, simple production change-overs

- Easier-to-use machinery

- Quicker deployment

- Extended equipment longevity

- Greater resale value

All of this means value, ease-of-ownership and on-going customizability that streamlines your operation and improves your production efficiency. The smart features and functionality native to JBT solutions can help you boost productivity, increase yields, lower costs, and improve product quality.

Meat Slicing & Portioning Made Easy

With the breadth of JBT portioning equipment available, we can target the machines that best accommodate your products, production lines, line speeds and changing product specifications. DSI Portioners use sophisticated systems to:

- Completely scan every piece of incoming product

- Analyze each piece for weight and shape

- Determine the optimum cutting paths to produce the desired final product

- Evaluate how best to use any remaining product area for additional products like cubes, strips, nuggets and more.

- Determine the most efficient path for the water-jet cutting heads to follow for fastest throughput

- Precisely cut products using high-pressure water jets to the exact shapes required

- X-ray guided systems can determine where bones are, and trim around them or through them at desired places

- All of this is done automatically and without human intervention

Reaching your goals – like achieving and maintaining high levels of product quality, reducing downtime, lowering production costs and increasing labor efficiencies – gets easier when you employ DSI portioning solutions. Operational successes go hand in hand with JBT products and services.

Made to Withstand the Tests of Time & Use

JBT equipment is built to last, with quality construction, state-of-the-art computers, robust components aimed for maximum durability, uptime, ease-of-use and easy sanitation. This is key because you likely don’t have the bandwidth or budget for downtime. It’s imperative to keep the food flowing through your machines, your workers busy, and your customers happy. For this to happen, you’ve got to have solutions that are robust.

We know full well the ramifications of unexpected production line stoppages. To prevent this, JBT equipment is made by skilled craftspeople using only the sturdiest materials and proven manufacturing techniques.

For you, this commitment to quality means:

- Easier and more cost-effective maintenance

- Maximum ease-of-use

- Minimized production issues

Features & Benefits

DSI’s food-portioning and slicing solutions come with all the cutting-edge features you’d expect from us. It’s these capabilities that make it possible for you to produce food quickly, precisely, and safely – over and over again.

- Efficient – Requires significantly less labor than manual processing

- Intelligent – Programmable to accommodate a wide variety of changing products

- Adaptable – Can cut multiple shapes at the same time

- Customizable – Modular and easy-to-integrate systems to meet changing product demands

- High-yielding – Automated systems scans food and selects cut strategy for maximum yield

- Innovative – Advanced hardware and software allow for continually-improved capabilities and flexibility

- Support – Worldwide service, support, and resources

Contact our team with any questions about these features – or how they can benefit your business.

Related Products

The JBT Family of Brands

You probably have enough things to occupy your mind and time. Worrying about the stability of your slicing machine, waterjet cutter or portioning equipment shouldn’t be one of them.

As manufacturers ourselves, we totally know the feeling and agree. It’s the reason we only carry the top marques – like DSI – that you know and trust. Our brands have earned their stellar reputations for operating safely and efficiently, yielding cost and productivity advantages, and more.

Comprehensive FoodTech Solutions

Every food product has different requirements. That’s why JBT offers an extensive portfolio of world-class machinery. In fact, at JBT you’ll find systems for industries and applications like:

- Injection and marination

- Pizza and baked goods

- Mushroom and salad slicing

You can get even more from your set-up with JBT’s upgrade kits, lubricants, and parts – as well as service, maintenance, and training.

Outfitting Your Entire Food Production Line

Whether you’re shopping for one piece of equipment or an end-to-end processing line, you’re in the right place. JBT provides you the quality, selection, and flexibility to tailor your facility’s set-up to your use case. Because of this, you can:

- Conveniently acquire your machines from a single supplier

- Customize your production line to suit your needs

- Blend brands to get the exact mix of machinery you need

- Replace or upgrade components of your current production line without hassle

- React to production changes with agility

- Scale your production more smoothly

Assembling your ideal production line couldn’t be simpler. JBT specializes in making this experience more pleasant and less hassle.

JBT, the FoodTech Partner That’s a Cut Above the Rest

Being in the food business can be complex and challenging. Fortunately, you’ve got JBT by your side. As a full-service solutions provider, we can help you with every aspect of food processing.

A Better, You-Centric Approach

At JBT, we’re proponents of a people-first mindset. The concept of ringing up a purchase and moving on to the next prospect is outdated and unsatisfactory.

Instead, we aim to establish productive and open long-term relationships with our customers. It’s the only way to get to know you and your business so we can serve you more thoughtfully and holistically. And, building rapport gives JBT an opportunity to show you the attention and respect you deserve.

Research & Innovation Hubs

Anything but an industry standard, our Research & Technology Centers are a unique and noteworthy benefit of working with JBT. These facilities are far more than mere test kitchens – they enable you to:

- Try out machines and explore production line configurations

- Perfect your recipes and preparation techniques

- Validate product quality and safety

- Connect with technical experts

- Leverage extensive data

Think of all the ways this could improve your production line and your bottom line…

Access to Experts

Having been leaders in the FoodTech industry since the 1880s, JBT has amassed deep knowledge and experience. This is a really good thing for you!

Our team wants your business to enjoy loads of success. It’s what motivates us to offer such premium-level support. We’re here to be your go-to resource for all things food processing.

Sometimes it’s just this extra bit of know-how that enables you to get the most benefit from your JBT products and services. Don’t hesitate to reach out anytime with your questions, concerns, and requests.