The Long, Rich History of our Post-Harvest Solutions

DESCRIPTION

You can have fresh fruits and vegetables tonight…even though the calendar says no! The reason is Flavorseal.”

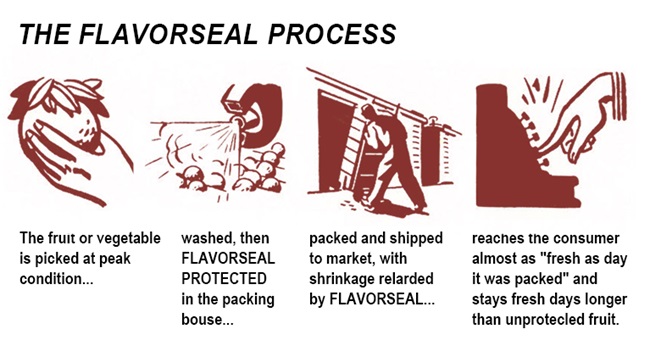

A development of FMC research chemists, Flavorseal is a solution which is sprayed in a thin, porous film over the entire surface of freshly harvested citrus fruits, tomatoes, cucumbers, and other produce. Applied in the packing house, Flavorseal slows down the natural deterioration of the fruit or vegetable…preserves its original freshness, flavor, and vitamin-content for many extra days or even weeks!

Later, FMC chemists concentrated on the further development of Floverseal – one of the many ways in which FMC research and engineering skill was being applied in the service of the nation. (Take a look at this vintage brochure)

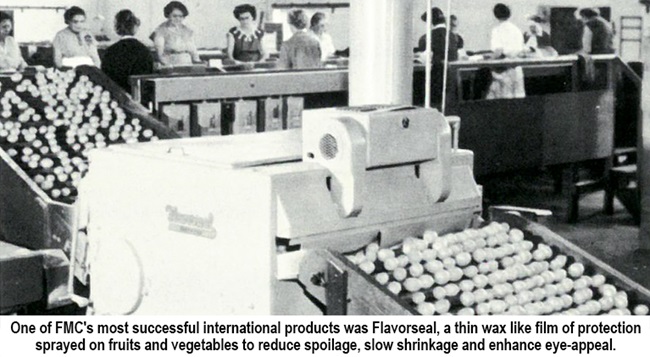

One of FMC’s most successful international products was Flavorseal. Marion Bames developed a worldwide marketing program targeting the areas of heaviest fruit and vegetable production. Bames, who was district manager for FMC’s Packing Equipment Oivision, considered one of his major achievemems to be securing the German government’s approvai for the materials used in coatings such as Flavorseal and Color-Added.

Beginning in the mid-1950s, Bames worked painstakingly with four groups of scientists – “they didn’t have the equivalent of our Food and Drug Administration” – located in Munich, Kiel, West Berlin and Hamburg. “lt was like a merry-go-round, meeting one week in Munich and the next in Hamburg, explaining how harmless our products were and citing their advantages”, said Barnes.

On a number of occasions Barnes returned to the United States to Cal Research, a division of Standard Oil of California, where tests were run on the coating products. He would then trave! back to Germany and present new datato theseparate boards-which would invariably ask for still more data. Meanwhile, che Germans were conducring cheir own tests and, accord ing to Bames, “confirmed that Flavorseal retained more vitamins than untreated fruir and reduced weight loss by 30 percent'”.

Finally, in late 1959, Bames was assured rhat the boards had approved Food Machinery’s products and it remained only for che Bundestag and Bundesrrat- West Germany’s legislative bodies-to grane final approvai. Bue Barnes’ high spirits were shattered when he received a cable (“about six feet long”) saying that FMC’s products would nor be allowed ineo Germany.

“I was absolutely crushed”, Bames recalled. Fortunately, che cable’s news proved to be totally unfounded. A day later Bames received another cable from one of che German scientists in Munich saying chat che products had been approved by the German govemmene. Wich that approvai, Flavorseal and ocher coating processes soon were deared for use in France, England, Italy and che Scandinavian countries.

PRODUCTS

Originally developed by the U.S. Oepartment of Agriculture, the process used a certified coloring solution, which was applied only to fruit that had already passed federai and state tests for juice content and ripeness. The fruit was first thoroughly washed, then dipped in the color bath, rinsed, dried and waxed to seal in the flavor. “Color-Added was basically John Crummey’s baby”, recalled Howard Shannon, who joined Food Machinery as a salesman in 1928 and would later manage the Florida Division for many years.“Mr.Crummey literally went into the markets with samples of colored oranges”, Shannon said “to show the benefits that would come from the process”.

Citrus packing houses eagerly embraced the new process. Leased at the cost of a few cents for every box of fruit treated, Color-Added soon became a major contributorto the Food Machinery balance sheet as well. Meanwhile, Food Machinery engineers and salesmen were helping food industry customers expand another fresh produce market: cantaloupes.

These fruits present a particular challenge togrowers because cantaloupes – unlike apples, pears or bananas – do not gain any more sugar content once theyare picked. Cantaloupes, therefore, had to be picked at what was called “hard ripe”, leaving little time for the fruit to be transported to distant markets. University researchers and melon specialists had finally succeeded in developing a cantaloupe that was resistant to mildew- the bane of melon growers’ existence. But Resistant 45, as the new strain was called, would hold its flavor and appearance only if picked at full maturity.

Food Machinery set out to find a wax coating that would keep the ripe fruit from drying out and rotting before it reached grocery store shelves across the country. After exhaustive and often frustrating experimentation, Art Kalmar, chief chemist at Riverside Oivision, carne up with a paraffin suspended in a solvent that could be sprayed on the cantaloupes as they rolled along a belt. By the time the fruit reached the end of the belt, the solvent had evaporated, leaving behind an even coat of wax.

Marion Bames, a Food Machinery salesman who had taken Color Added and other processes worldwide, soon realized that the same process might be applied to other fruits and vegetables. Recently transferred to Harlingen, Texas, as processing manager and assistant divisional manager, he tumed his attention to tomatoes. After experimenting at length with different solvents, various wax formulations and orifice sizes, he found an improved solvent and better grade of paraffin, and determined that toma toes required less wax than did cantaloupes. “The experiments turned out very welI” “he recalled,“so I signed up five large houses in Texas before we actually had a unit”.

The Spray Wax process was used on beli peppers and cucumbers as well, with each variety of produce requiring its own blend of waxes and solvents. By the late 1930s, Spray Wax was beginning to sound too pedestrian for so successful a process.”Severa! of us submitted names for the new wax”, Bames recounted. “FrankCutler from Cutler Manufacturing submitted the name Flavorseal,and that was the winner”.

Flavoresal, like Hypo-Clor and Color-Added , was a leased process, furnished on a servicecharge basis with equipment and materials supplied by Food Machinery, which also provided ali the maintenance and supervision (For tomatoes, for example, the company received three cents per 30-pound lug.). lt soon became one of the company’s most successful products.

BROCHURE

For more information, read the following brochures:

90 Years of History

Contact Us

If you have any comments or questions, please email francisco.peris@jbtc.com