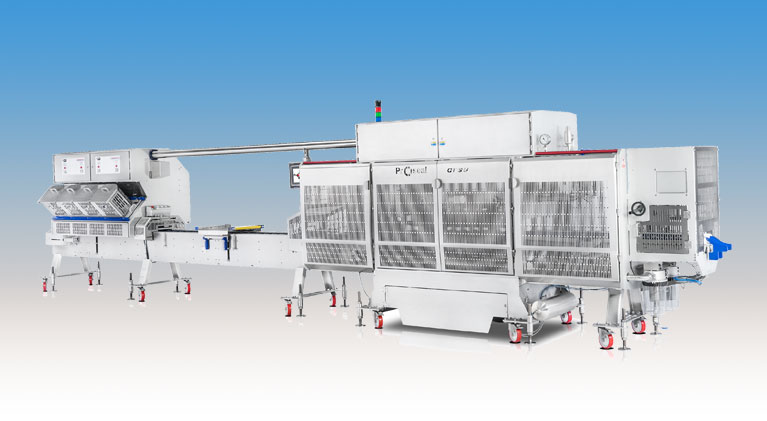

The Proseal GTSV is the world’s first MA (Modified Atmosphere) carton sandwich wedge erecting and sealing machine.A high throughput carton sandwich wedge de-nest and erect, Vacuum/Gas sealing machine, capable of up to 50 packs per minute in the Vacuum Gas cycle. An Atmospheric Seal mode is available, capable of up to 70 packs per minute. This machine has a unique three axis carton sandwich wedge transfer system, enabling the sandwich cartons to be conveyed on hygienic carriers that have a single point size adjustment.Able to handle a wide variety of carton sandwich wedge sizes, and with a sub 5-minute size change over, the GTSV is perfect for users requiring maximum throughput with the minimum of labor.The GTSV has station options for label applicators and printers offering the customer a turnkey production line solution for carton sandwich packaging.

Features & Benefits

- Fully automatic carton de-nesting and erecting with quick size change

- Food industry approved hygienic construction and wash-down protection

- Fully integrated control of machine and ancillary equipment

- Servo driven 3 axis carton sandwich wedge handling system for perfect presentation

- Automatic carton sandwich wedge eject

- Can run carton widths up to 110mm with ultra-quick size change

- Self-diagnostic system

- V style out feed conveyor gives excellent presentation of packs to Laser date coders and labeling equipment

- Fully portable and castor mounted

- Food industry approved hygienic construction and wash-down protection

- Simple design and operation

- Eseal® energy efficient electric seal system that boasts a massive increase in seal force and a 92% reduction in energy consumption.

- ProMotion high accuracy continuous motion tray infeed system, which increases production speed whilst reducing machine duty.

- QR Conveyors with quick release belts for easy hygiene and maintenance

Details

- Fully automatic carton de-nesting and erecting with quick size change

Options & Models

- eWON a machine connection system to deliver real time data and error condition support, remote setup, and software upgrades, using a customer’s existing IT network

- ProTect a contactless machine login and audit trail system

- All around seal only (No Cut) for packs with pre-cut or hinged lids

- Free flow gas flush MAP (Modified Atmosphere Packaging

- High Oxygen (O2) gas flush

- Close Cut – Method of maximizing throughput and reducing film waste

- Film coding and printing

- Sandwich Pack Sealing for Board, Recyclable and Non-Recyclable Plastic

- Optional Control Integration of peripheral equipment, such as: de-nesters, fillers, multi-head weighers, laser coders, labelers.

- Hot Rod – long-lasting, water-resistant seal, tool-heating element giving reduced energy consumption especially developed for sealing Smooth Wall Foil Trays

- Sale, Lease Purchase and Rental options available