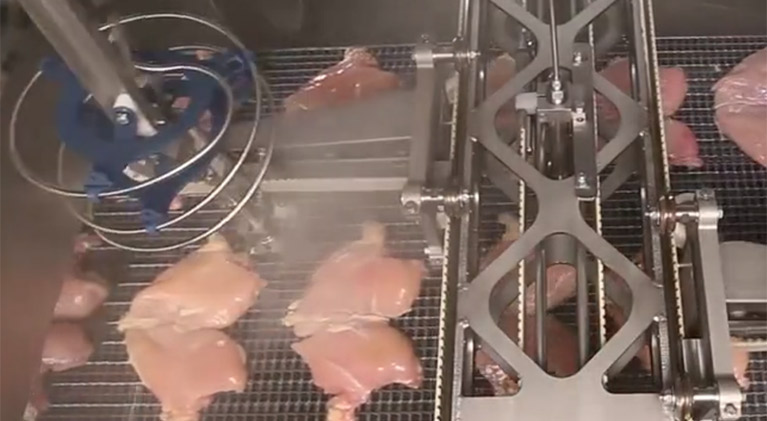

The Proseal AP60 is a linear conveyor, tray sealing system capable of sealing up to 240 packs per minute. The AP60 provides the flexibility required by food producers looking for a fully automated turnkey production line. The customer can specify the length and width of the indexing conveyor to accommodate their tray de-nesting and filling requirements.Optional ‘free-flow’ gas flush Modified Atmosphere Packaging (MAP) available for extended shelf life.Easily integrated with other production line equipment.

Features & Benefits

- Modular design allows customer to specify conveyor length, width and tray pitch

- Variable pitch indexing conveyor will accommodate tray and lid dispensers, filling and weighing heads

- Fully integrated control of machine, tray and lid dispensers, filling and weighing heads

- A high specification conveyor drive system provides full control of the linear acceleration, deceleration and velocity of product movement and eliminates spillage

- Automatic tray eject allowing post seal operations to be carried out efficiently

- Fully portable and castor mounted

- Food industry approved hygienic construction and wash-down protection

- Simple design and operation

- Eseal® energy efficient electric seal system that boasts a massive increase in seal force and a 92% reduction in energy consumption.

Details

- Designed to perform following styles of heat seal to a pre-formed tray; Atmospheric, Gas Flush, Vacuum Gas and suited to all relevant food categories including; Fish and Seafood, Pork, Red Meat, Poultry, Soft Fruit, Fresh Produce, Ready Meals and Desserts.

Options & Models

- eWON a machine connection system to deliver real time data and error condition support, remote setup, and software upgrades, using a customer’s existing IT network

- I-film intelligent film reel monitoring system which actively adjusts film tension based on reel diameter to increase print quality and film reel efficiency, reduce component duty, and provides a film end warning system.

- ProTect a contactless machine login and audit trail system

- Automatic tray de-nesting

- Automatic lid pick and place

- Automatic lid over-capping

- Integrated air and electrical outlets along the machine length

- for auxiliary equipment

- Film coding and printing

- Sandwich Pack Sealing for Board, Recyclable and Non-Recyclable Plastic

- Optional Control Integration of peripheral equipment, such as: de-nesters, fillers, multi-head weighers, laser coders, labelers.

- Hot Rod – long-lasting, water-resistant seal, tool-heating element giving reduced energy consumption especially developed for sealing Smooth Wall Foil Trays

- Sale, Lease Purchase and Rental options available