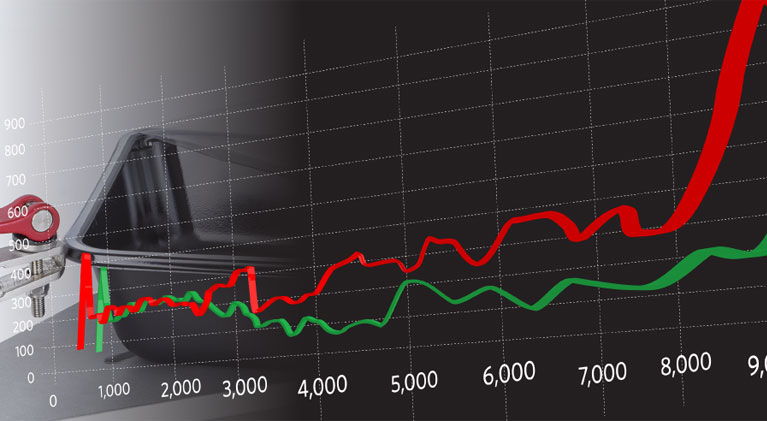

We are often asked the question: ‘What defines a good seal?’Whilst existing test equipment is able to test the burst strength of a seal and the limits of the pressure or weight it may support, until now, there has been no available equipment able to measure the ‘peelability’ of a tray.The Proseal ProTest is able to analyze, record and report the force required to peel a lid from a tray, enabling the user to determine if the seal strength is suitable for the product’s life-cycle. The ProTest is an automated lid peeling device, designed to measure and report the resistance offered by the film as it separates from the tray during the moment of lid peeling.With its easy setup, the user can specify the strength of peel required for the specific product, process, material or environment of their production facility. Having a ProTest on site gives up-to-date, line-by-line seal integrity analysis, cutting out the need to send samples off-site for costly, third-party testing.The ProTest is capable of retaining, displaying and outputting test data, allowing the user to export the information. Once exported it’s possible to compare up to five test results against one another simultaneously, in a variety of formats.

Features & Benefits

- User-friendly interface for simple operation

- Robust and self-contained

- Requiring only 1200mm x 400mm of bench space

- Easy data export via USB or Ethernet connection

- Having a ProTest on site gives up-to-date, line-by-line seal integrity analysis, cutting out the need to send samples off-site for costly, third-party testing.

Details

- A peelability test is achieved in five easy steps:

- Switch on the unit

- Choose which tray from your production you wish to test

- Secure it, using the specially designed film clamp and tray support

- Fill in some details to identify the materials and parameters before testing

- Press go

- By employing a ProTest unit, the user is able to establish their own Peelability Metrics for the specific tray size, tray material, film, and process.

- ProTest is designed to be flexible to suit the vast majority of trays used in the market place.

- The maximum pull the machine is capable of is a diagonal tray diameter of 380mm. There is no limit to the shape of the tray, or a minimum diameter required.