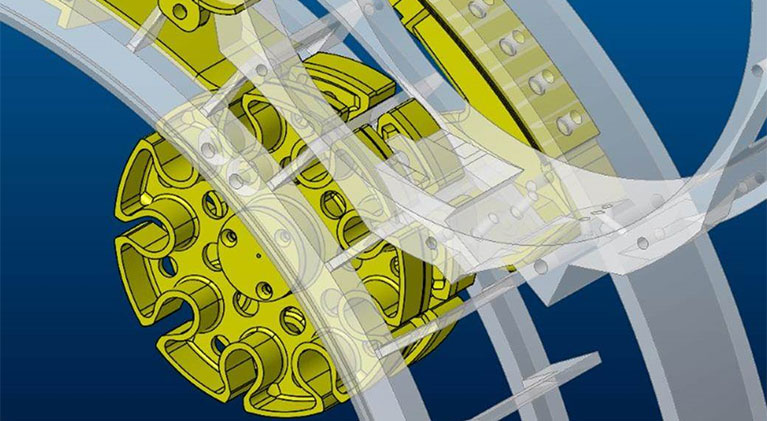

Our GCH technology creates a tangential path for metal cans to transfer from shell-to-shell in a Rotary Pressure Sterilizer (RPS) as gently as possible so as to minimize can damage. The tangential path maintains can control as the ejector lifts the can out of the reel and over the leading edge of the valve bridge. This motion reduces sharp impacts experienced by lighter weight can in high speed lines.The technology can be applied to both new RPS equipment, as well as, retrofitted to existing RPS equipment.

Our GCH technology creates a tangential path for metal cans to transfer from shell-to-shell in a Rotary Pressure Sterilizer (RPS) as gently as possible so as to minimize can damage. The tangential path maintains can control as the ejector lifts the can out of the reel and over the leading edge of the valve bridge. This motion reduces sharp impacts experienced by lighter weight can in high speed lines.The technology can be applied to both new RPS equipment, as well as, retrofitted to existing RPS equipment.

Features & Benefits

- Reduced can damage

- Enables usage of lighter weight cans, and necked-in cans with or without body chime

- Faster equipment speeds; therefore, increased throughput

- Smoother transfer into can valve

- More forgiving transfer parts setup

- Reduced frequency of transfer jams

Details

- Available in new RPS units or as a retrofit kit for existing units