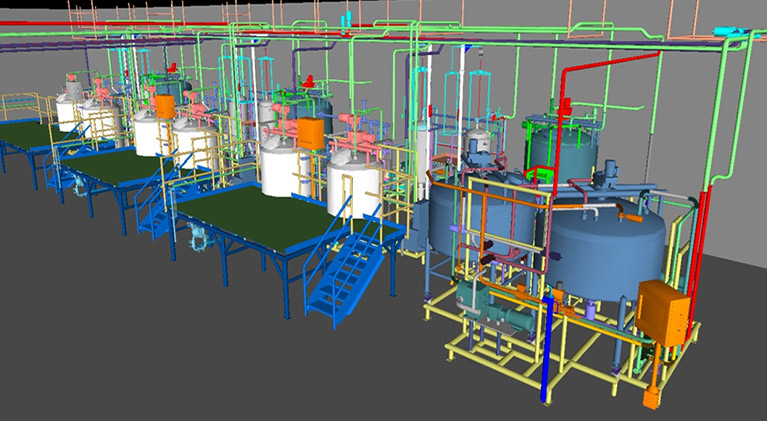

At A&B Process Systems, our piping installation experts work with the process engineering designers, whether it’s your team or ours to provide a complete plant installation and integration project. We have an extensive crew of OSHA and ASME trained personnel that are skilled in sanitary/high purity piping installations for a variety of markets.Our skilled crews utilize 3A design practices, equipment rigging/setting, demolition and relocation of process systems and equipment expertise to meet your critical requirements. If Orbital welding is your project requirement, A&B has the experienced staff to meet your exact specifications to provide the quality you deserve in a Process Piping installation partner.Our knowledgeable field piping crews utilize state of the art Web-based Project management software to keep you updated on accurate project status in real time so you know how the project is progressing during all phases of the project.Please reach out to our sales team to discuss how A&B can assist you with making your next project a success.

Features & Benefits

- 40+ year experience in Process Systems design and sanitary piping installation practices

- Large installation employee base to handle small to large projects exceeding 20,000 feet of piping. (over 8 million feet installed to date)

- Extensive safety program and Good standing safety record

- Licensed to perform installation services in the US, Caribbean and Mexico

- Highly skilled staff with experience in Food/Beverage, Dairy, Pharmaceutical, Nutraceutical and Cosmetic industries

- Lean manufacturing practices to reduce waste during project life cycle and increase productivity onsite

- Web-based Project management software to track progress in real-time and to provide accurate project updates

- Single-Source offering for supply of Process design, Process system equipment and installation services

- Customer Care offering after the sale to assist the customer with ongoing Preventative Maintenance programs and repairs