Simplify your production lines and achieve higher efficiency and better quality with the most versatile injection technology on the market

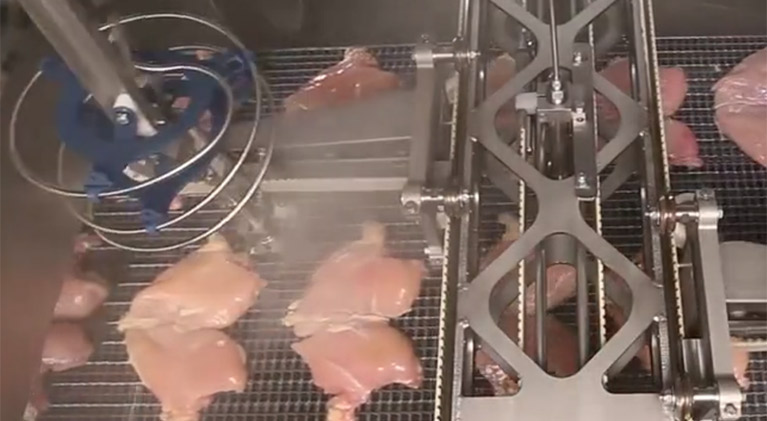

The customizable MEPSCO UltraCAT Double Head Injector is designed to maximize precision and increase the speed of processing bone-in and boneless meats while saving you the hassle of extensive maintenance.

In keeping with JBT’s broad commitment to simple, yet versatile food processing equipment, this double-head meat injector offers a 244, 278, or 488 needle injection head or a 244, 378, or 488 needle tenderizer head for boneless meats. This allows you to configure the machine for any process with production rates up to 40,000 pounds per hour with 3% to 83% on a single pass with uniform distribution, superior moisture retention, and ideal piece-to-piece consistency.

The UltraCAT Double Head Injector is also equipped with a self-cleaning filtration system, so you can achieve maximum efficiency and better product quality across a range of processing applications while reducing the need for maintenance and service.

Features & Benefits

The MEPSCO UltraCat Double Head Injector offers seemingly endless high-tech, customizable solutions to serve your needs and help you meet your system and business goals. JBT has developed a cutting-edge machine that revolutionizes the injection process. With the UltraCAT, we’re putting the control in your hands while providing superior speed and efficiency, as well as improved automatic sanitation technology.

- Multiple needle configurations – With 3mm, 4mm, and 5mm needle-sizing options, the ability to operate with 244 to 976 needles per machine, and flexible spacing options, the UltraCAT’s injection needles can be configured to suit your specific processing needs.

- Modular conveyor belt – Modernized conveyor technology allows for greater flexibility of use, a simplified cleaning process, and a lower overall cost of ownership.

- Increased production rates – With flexible configurations of single or double head injectors along with tenderizer options and customizable injection speeds up to 55 strokes per minute, you can achieve production rates of up to 40,000 pounds per hour.

- Consistent distribution – The UltraCAT allows for 3% to 85% injection ranges on a single pass with uniform distribution, superior moisture retention, and unmatched accuracy.

- Self-cleaning – The state-of-the-art filtration system utilizes a rotary drum to eliminate up to 95% of solids while dual inline filters for each injection head filter out additional solids to significantly reduce contamination concerns.

Superior Hygiene & Safety

The food-processing industry represents some of the harshest environments for electronics and mechanized parts – especially where meat, poultry, and seafood are concerned. JBT remains committed to producing equipment that adheres to the highest standards of sanitation, hygiene, and user safety.

Like all JBT FoodTech solutions, our meat injection machines and meat tenderizers are designed to flourish under the most demanding production conditions. We’re committed to upholding the most rigorous standards of safety in all we do, and we offer comprehensive training programs and preventative maintenance plans to ensure your equipment continues to operate smoothly and effectively for the long term.

FAQs

What products can be processed using the UltraCAT Double Head Injector?

The UltraCAT’s versatile design, which accommodates 244, 378, or 488 needle injection or tenderizer heads, makes it ideal for processing a wide variety of bone-in and boneless meat products. Whether you’re processing pork bellies, poultry, or seafood products, the UltraCAT meat injector and tenderizer machine can be configured to suit your specific needs and objectives. The injector’s impressive 112-gallon brine holding tank and quick-change needle modules also ensure you don’t have to sacrifice efficiency to achieve superior results.

What are the primary maintenance requirements for the UltraCAT Double Head Injector?

At JBT, we understand that extensive maintenance requirements can significantly reduce uptime and impact your bottom line. That’s why we design our machines to be as self-sufficient as possible. The UltraCAT boasts ultra-hygienic stainless-steel surfaces and its high-tech filtration system reduces time and labor spent on manual cleaning. Additionally, when replacement parts or repairs are needed, JBT’s expert support team is available 24/7 to provide you with the specific parts and assistance you need to get your operation up and running in no time.

Does operating the UltraCAT Double Head Injector require training?

The UltraCAT is designed to be simple and easy to operate using the accompanying Allen Bradley CompactLogix controller, which features a 7” PanelView Plus touch screen. With an intuitive interface, the controller includes 100 product presets to automatically set the injector to accommodate specific product specs. It also contains maintenance screens with trouble-shooting instructions and a sanitation mode.

JBT – Revolutionizing FoodTech Since 1884

When JBT first opened its doors as the Bean Spray Pump Company over a hundred years ago, we had one simple yet ambitious goal – to redefine what’s possible in FoodTech. With our unrivaled determination, in-depth understanding of food-processing technology and markets, and a genuine dedication to serving our partners, we’ve solidified the JBT name as a true leader and industry powerhouse.

We’ve always believed that collaboration is at the heart of success. Our approach revolves around developing long-term, mutually beneficial business relationships with food processors throughout diverse markets around the globe. With JBT, you get more than just an equipment provider – you get an experienced industry partner you can trust.

State-of-the-Art Research & Technology Centers

JBT is dedicated to continued innovation. We believe that through rigorous research and technological advancement, we can simplify and improve the food-processing industry and create a better, safer, and more inclusive future. As a JBT partner, you’re invited to join us at our global Research and Technology Centers and work directly with our FoodTech specialists as you test new equipment, refine your recipes, and experiment with different production-line setups and configurations. Working together, there’s nothing we can’t accomplish!

Industry-Leading Expertise, At Your Service

At JBT, we don’t just produce the highest quality machinery in FoodTech. We go above and beyond to ensure we’re available to offer guidance, support, service, and training to our partners. We take the time to understand the specific challenges you face in your markets, and we’re here to offer individualized, comprehensive solutions to meet your needs.

Our experts are here to help around the clock. Contact us to learn more about our offerings, get your questions answered, and join the JBT family!