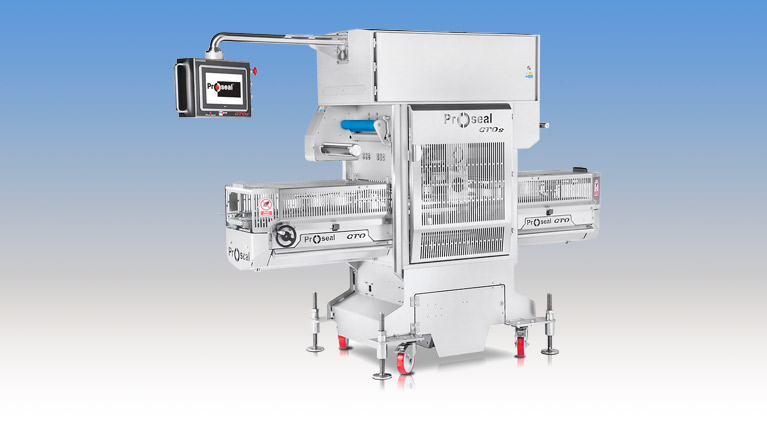

La Proseal GT0s es un sistema automático de sellado de bandejas en línea de alta velocidad y capacidad media diseñado para reducir los costes de mano de obra.

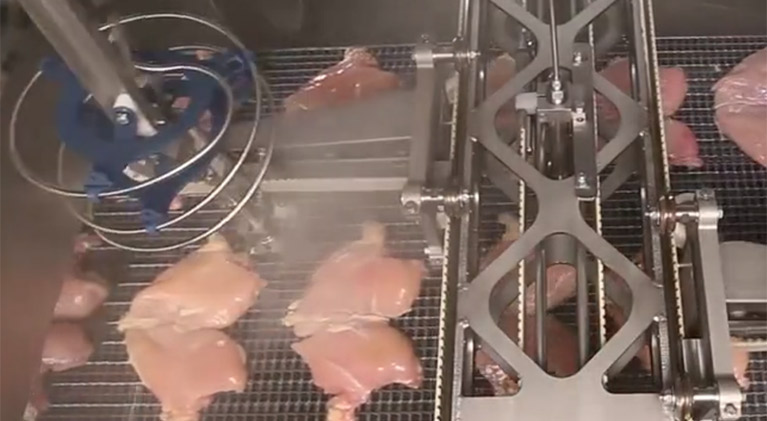

Combina un alto rendimiento con un cambio rápido de herramientas y un diseño compacto que ahorra espacio. Envasado en atmósfera modificada (MAP) con flujo de gas libre opcional para prolongar la vida útil. Con una capacidad de hasta 36 envases atmosféricos por minuto con una herramienta de 2 impresiones, el sistema GT0s está repleto de ventajas fáciles de usar, incluido nuestro exclusivo sistema de transportador modular QR. Diseñado para aceptar bandejas espaciadas aleatoriamente desde cualquier transportador, el GT0s puede integrarse totalmente con otros equipos de la línea.

Características y ventajas

- Cambio de herramienta en dos minutos

- Totalmente portátil y con ruedas

- Construcción higiénica aprobada por la industria alimentaria y protección contra el lavado

- Diseño y funcionamiento sencillos

- Sistema de sellado eléctrico energéticamente eficiente Eseal®, que ofrece un enorme aumento de la fuerza de sellado y una reducción del 92% del consumo de energía.

- Sistema de alimentación de bandejas de movimiento continuo ProMotion de alta precisión, que aumenta la velocidad de producción a la vez que reduce el trabajo de la máquina.

- Transportadores QR con correas de liberación rápida para facilitar la higiene y el mantenimiento.

Detalles

- Diseñado para realizar los siguientes estilos de sellado térmico a una bandeja preformada; Atmosférico, Gas Flush o Hermetic Shrink, y adecuado para todas las categorías de alimentos relevantes, incluyendo; Pescado y Marisco, Cerdo, Carne Roja, Aves, Fruta Blanda, Productos Frescos, Platos Preparados y Postres.

Opciones y modelos

- eWON un sistema de conexión de máquinas para ofrecer datos en tiempo real y asistencia en caso de error, configuración remota y actualizaciones de software, utilizando la red informática existente del cliente

- Sistema inteligente de control de la bobina de película I-film que ajusta activamente la tensión de la película en función del diámetro de la bobina para aumentar la calidad de la impresión y la eficiencia de la bobina de película, reducir el trabajo de los componentes y proporcionar un sistema de aviso de fin de película.

- ProTect, un sistema de registro y auditoría de máquinas sin contacto

- Máquinas de envasado en blíster para productos farmacéuticos

- Sellado de paquetes sándwich para cartón, plástico reciclable y no reciclable

- Flujo de gas libre MAP (envasado en atmósfera modificada)

- Descarga de gas con alto contenido de oxígeno (O2)

- Close Cut - Método para maximizar el rendimiento y reducir el desperdicio de película

- Opción de corte interior (IC) para proporcionar una presentación de la bandeja "formar, llenar y sellar

- Codificación e impresión de películas

- Engaste de láminas

- Transportadores activos que permiten utilizar la máquina como un transportador directo cuando los paquetes no necesitan ser sellados

- Configuraciones de máquinas consecutivas

- Integración opcional de equipos periféricos, tales como: desempacadoras, llenadoras, pesadoras multicabezales, codificadoras láser, etiquetadoras.

- Opciones de venta, compra y alquiler disponibles