ABOUT

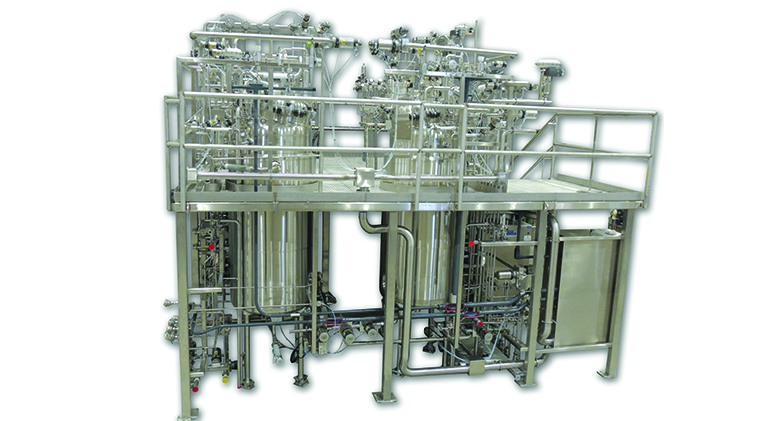

The project would feature the bespoke design of two bioreactor skids – one bioculture and another for dual use, with tanks, automation and platforms – as well as three Clean-In-Place (CIP) skids and two biowaste systems.

SUCCESS

The project from initial brief to final installation was a 14 month process, which involved 3-D modelling, weekly meetings through every phase of design and manufacture, leading up to final integration into the facility. A&B Process Systems carried out 3D modelling, manufactured and provided the reactors and skidded system, installation of wiring and electrical and acceptance tested after completion. Because of A&B Process Systems in-house capabilities, we’ve received a lot of positive feedback from the customer.

CONTACT US

We’re here to help every step of the way.

Sales Questions

Get Support

More Our Brands

- A&B Process Systems

- alco

- AutoCoding Systems

- Avure Technologies

- Bevcorp

- Cooling & Applied Technologies (C.A.T.)

- Double D

- DSI

- Formcook

- FranRica

- Frigoscandia

- Fresh’n Squeeze

- FTNON

- JBT

- JBT Control Systems

- MEPSCO

- Northfield

- PLF International

- Prevenio

- Prime Equipment Group

- Proseal

- Schröder

- SF&DS

- Stein

- TIPPER TIE

- Urtasun

- Wolf-tec