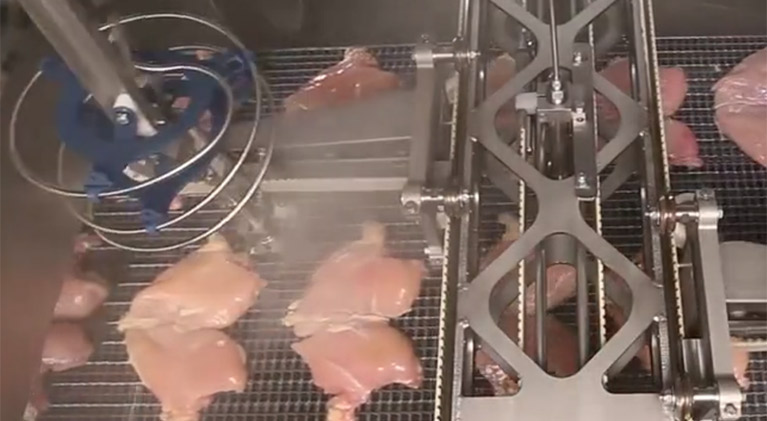

Bone-in or boneless meat Injection

The versatile ULTRACAT Junior injector is designed and manufactured in the USA to set the pace for controlled injection of bone-in or boneless meats. With needle configurations of 210, or 280 and production rates up to 12,000 pounds per hour, MEPSCO injectors from JBT lead the way in uniform distribution, best moisture retention, and superior piece-to-piece accuracy. The efficient filtration system features a self-cleaning rotating drum filter to eliminate 95% of the solids and dual pressure filters to filter out additional solids before going to the needles.

Features & Benefits

- EASY CLEANABILITY with stainless steel surfaces and an efficient filtration system that boasts a self cleaning drum filter to eliminate 95% of solids. Dual pressure filters also significantly reduce any additional solids before going into the needles.

- CONSISTENCY & ACCURACY with a programmable touch screen

- VERSATILITY enhances the different products and profiles on the same machine

Details

- Needles up to 280 special alloy stainless steel standard needles or optional tenderizer needles, both available in sizes: .118” (3 mm) .158” (4 mm) .188” (5 mm)

- Fully adjustable injector speed up to 55 strokes/minute

- Up to 85% injection range from a single pass (product dependent)

- Optional 1-way (down) or 2-way full flow (up & down) brine valve

- 60-gallon brine holding tank

- 5-stage brine filter

- 25 hp at 460V (35 amp), 3-phase, 60Hz

- 80 PSI air 3/8” npt 1½” brine connection

- Quick change needle manifold

Options & Models

- 210, or 280