Advanced sterilization systems that reduce processing time while ensuring precise temperature and pressure control

What if you could save time and energy but still guarantee the pressure and temperature needed to ensure sterilization? Imagine achieving your target food safety and shelf-stability objectives with lower costs and greater productivity. That’d be a welcome adjustment to your production line.

We think so, too. JBT’s ready to help you streamline your food and pharmaceutical manufacturing with retort machines designed for:

- Automated hardware integration

- Energy efficiency

- Steaming, cooling, canning

- Container flexibility

- Sanitation and sterilization

Plus, our specialists work with you to determine the ideal batch retort solution for your processing needs. It’s what makes JBT batch retort processing equipment so successful in so many markets, like:

- Baby food

- Fruits and nuts

- Juices and beverages

- Oils, soups, sauces, seasonings, and dressings

- Poultry, meat, and seafood

- Ready meals

- Pet food

- Dairy and dairy alternatives

- Pharmaceuticals

JBT offers the total retort processing package you’re looking for. Together, we can improve your operations and your outputs in the best possible way.

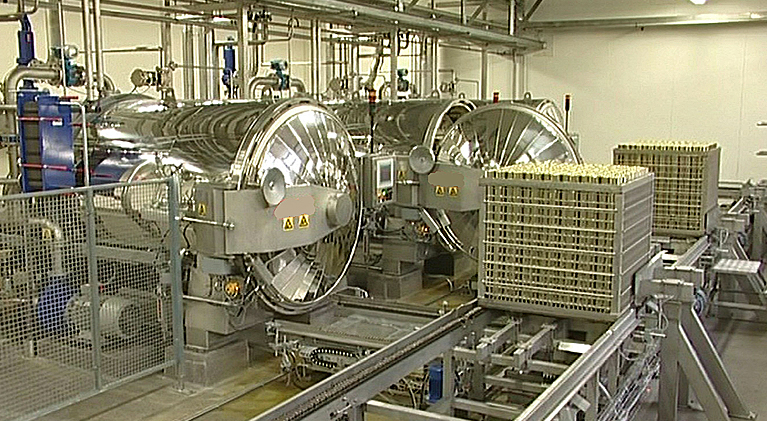

Automated Batch Retort Systems (ABRS)

When you need fully automated integration of all hardware (including the retorts), our ABRS is the answer.The ABRS is designed for the transportation of baskets […]

Get details

SuperAgi™ – Agitating Batch Retort

In our SuperAgi sterilizer the light perforated plate structured drum closely links to the basket – with spray pipes integrated in the drum. The vessel measures […]

Get details

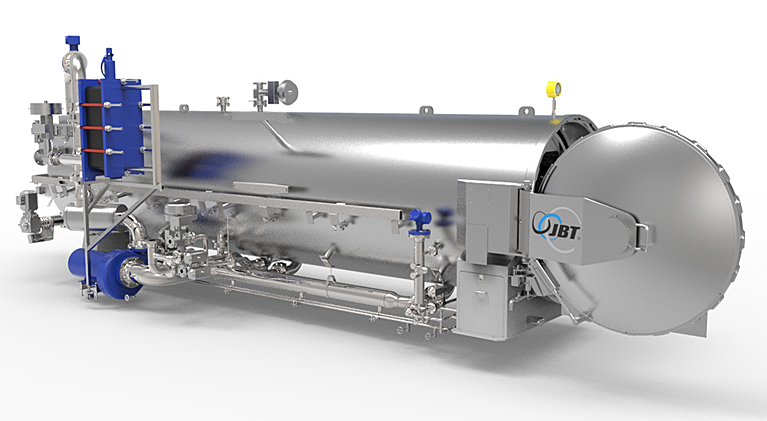

SuperCRss™ – Batch Retort

A fully automated retort that processes cans of all sizes and volumes from large foodservice cans to small retail cans. The SuperCRss sterilizes foods such […]

Get details

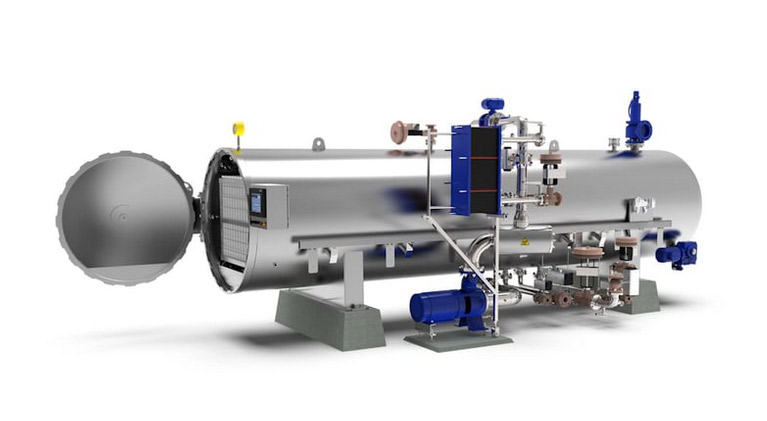

Static Retort – Steam Water Spray™ (SWS)

Steam is directly injected in the bottom of the retort for fast and uniform come-up. Water sprays running over the entire shell length intensely mix […]

Get details

SuperStatic Retort

Increase your bottom line by saving process time, floorspace and energy. Sterilize foods such as beans, fruits, vegetables, meat, soups, and pet food.

Get details

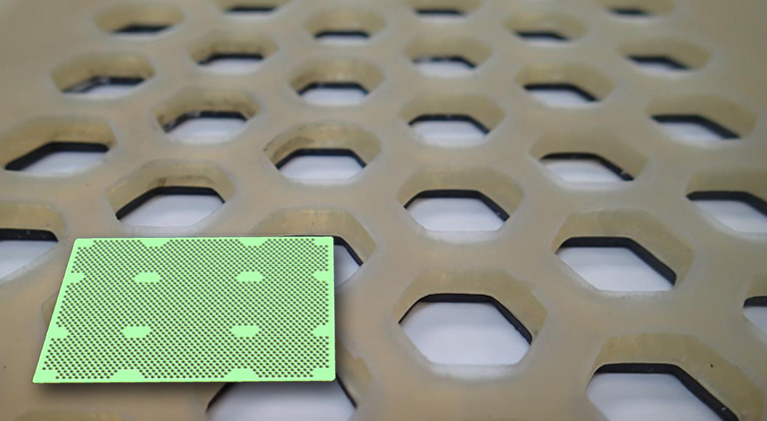

Hybrid Layer Pad

A technology break-through for Super-Agi™ agitating retorts, the Hybrid Layer Pad is specifically designed to securely hold irregularly shaped bottles or containers during rocking or […]

Get details

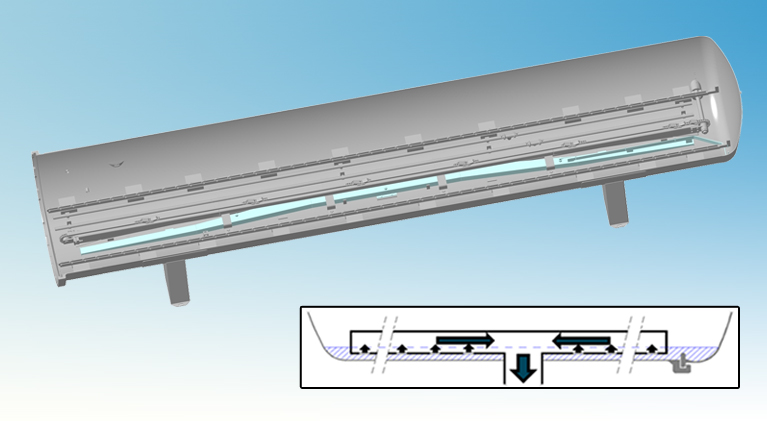

Low Energy Suction System

A technology break-through for static Steam Water Spray (SWS) retorts, our Low Energy Suction System (LESS) provides food processors more energy savings by employing a new, bolt-on system […]

Get details

Efficient Agitation System

EA provides recipe-driven linear motion within the retort to add product agitation which leads to faster product heating and cooling.

Get detailsContact our team today with any questions about these products or how they benefit your operations.

JBT Retort Food Processing, Always a Smart Choice

Sanitizing food with JBT’s processing equipment makes good sense for a bunch (or batch!) of reasons. In fact, we’ve earned an admirable reputation in the industrial food manufacturing machinery space precisely because we bring so much value to the factory floor.

In addition to lower ownership costs and best-in-market resale value, there are plenty of other driving factors for this. Our food processing equipment – much more than mere autoclaves, industrial coolers, and industrial cookers – is packed with truly intelligent and useful features and options.

- Options for fully automated integration of all hardware (including the retorts)

- Models with high holding capacity accommodate a large range of container types

- Fast and uniform processing

- Homogeneous temperature distribution

- Indirect, sterile cooling via a plate heat exchanger

- Saves water and eliminates the need for water treatment chemicals

- Significantly decreases heating and cooling costs per process

- Can securely hold irregularly shaped containers during rocking or agitating

- LOG-TEC thermal process control monitors the retort system

- Basket Tracking System (BTS) coordinates and tracks basket movements

- Advanced technology

Can you imagine JBT’s sterile food processing machinery plugging away in your facility? With all of these capabilities, you can be confident that your food production is consistently as productive, accurate, and safe as possible.

Why Choose JBT

Your job is complex enough. Work with JBT – we can make it simpler and generate better results. That’s a great deal!

JBT’s extensive portfolio includes an assortment of products, services, and support to address the never-ending challenges of running a business. We’ve got the solutions an industrial food processor like you could possibly require.

There’s no need to look farther afield than JBT for seamless and efficient food production operations. We’ve got more than just machines to support your operation.

Best Selection of FoodTech

That JBT steam retort machine you have in the production line is a stellar piece of food processing equipment. We can’t argue there. However, it does not form the complete set-up needed to make your product.

Anticipating your broader needs, we have a wide product lineup that includes other high-performance JBT FoodTech for tasks such as:

With the breadth of heavy-duty food manufacturing machines that JBT offers (not to mention our upgrade kits, parts, detergents, and lubricants), it’s no wonder you’ll be able to:

- Conveniently shop for equipment with one supplier

- Tailor your production line to suit your needs

- Mix and match brands to get exactly what you want

- Replace single components of your current set-up or assemble a full production line

- Agilely respond to product, process, or regulatory changes

- Smoothly scale operations

JBT hardware is deployed at companies around the globe. Why? Industrial food processors trust JBT because we deliver – over and over again.

Excellent Software & Services

Top-shelf machinery isn’t all JBT’s able to offer you. We also take customer care seriously. We’re happy to offer:

- Software, like iOPS® and ProSIGHT™, to better manage your operations

- Training in areas such as operation/maintenance, control systems, and food safety

- PRoCARE® to make preventive and maintenance care for your equipment easy

Software or services are often the key to getting discrete supplies and equipment, operations, and personnel to gel into a cohesive, high-functioning system.

Innovation & Testing Hubs

JBT’s Research & Technology Centers are one customer perk that sets us apart. These unique and remarkable facilities are available to you so you can try out machines, explore production line set-ups, perfect your recipes and techniques, and access to technical expertise and data. They are truly so much more than just test kitchens or labs!

Your Partner in Food Processing

In today’s complex manufacturing and marketing environments, the logistics and decisions involved in running a food business can seem overwhelming. With JBT at your side, you aren’t facing the chaos alone. We’re a team whose combined force can make your operation more manageable and prosperous.

At JBT, we take the long view – one that looks beyond a single sales agreement. Our aim is to establish a lasting, collaborative relationship with you. It’s the best way we know of to:

- Help you get the most out of your investment

- Let us show you the attention and respect you’re due

- Strengthen your business and ours

You can count on us to be here for you before, during, and after your purchase. Our experts are on hand to assist you anytime.

The Comprehensive Solutions You Need

JBT is the smart solution for your end-to-end FoodTech needs. We offer all the equipment, services, and support you require and are ready to help you. Contact us today to see how we can improve your food manufacturing operations.

CONTACT US

We’re here to help every step of the way.