Sustainable Solutions

ESG at JBT | Efficient Operations | Vibrant Workplace

In 2022, we expanded our portfolio with an emphasis on sustainability, digitization, and automation. Our solutions helped customers maximize efficiency, reduce food and packaging waste, and increased product shelf life and yields. We also helped our customers up-skill their employees, streamline their processes, and reduce utilities and related costs. These efforts are core to our mission and add up to a shared vision to create food systems that better serve us all.

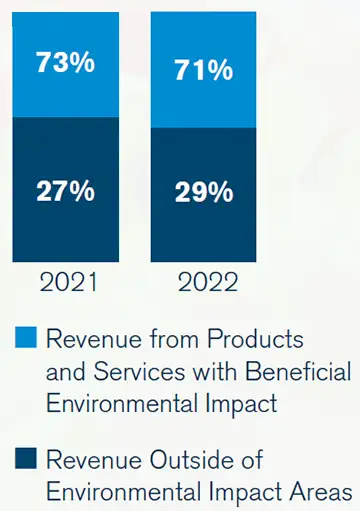

~71%

ESTIMATED PRODUCT REVENUE

from equipment that delivers environmental benefits

Customer Solution: Delivering Best-in-Class Quality & Growth

When the coconut water production company Silk Grass Farms wanted to grow their operations, JBT provided a turnkey solution. From technologies for fruit handling and production from FTNON to HPP equipment from Avure, we supported them with a range of products and services tailored to meet their needs—both now and into the future. “We were looking to invest and grow to become a sustainable agribusiness that can support the vision of the company: investing in our local community, our people, and creating a business that could preserve and protect a 27,500-acre tract of land located in Belize,” said Henry Canton, executive director of Silk Grass Farms. Learn more about our partnership.

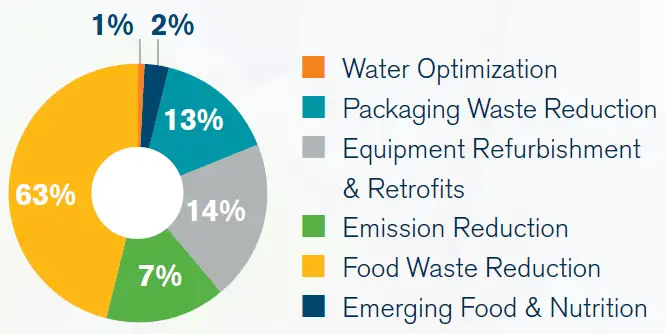

How We Help Engineer a More Sustainable World

Our food and air travel support technologies represent scores of different products across a wide variety of applications. A common attribute, however, is their ability to help customers use natural resources more efficiently. Here are some of the customer objectives that our products enable.

Customer Solution: Reimagining the Modern Food Processing Factory with Norsk Kylling

When Norway’s leading poultry producer, Norsk Kylling, planned its new production facility, the company had clear goals in mind, create a signature building that put sustainable food production, Norwegian agriculture, and animal welfare first.

JBT proved an ideal collaborator—providing a dedicated team to support the project at every step. Energy-smart solutions were core to the build, as Norsk Kylling wanted to leverage renewable solutions.

“Among other things, we invested in electrification and focused on energy flexibility, primarily through energy storage,” said Norsk Kylling’s Project Leader Håvard Staverlökk. “The plant is built for zero emissions and uses only renewable energy, and we have reduced GHG emissions by 100% compared with our old factory.” Learn more about our partnership.

Customer Solution: Saving Resources at HKScan

For our customer HKScan, a large producer of meat, plant-based, and ready meals based in Sweden, the LVS refrigeration system is an ideal energy-smart solution. The system has enabled HKScan to save on hot gas, leftover energy often available in large quantities in refrigeration systems, which can be used to defrost freezers.

“With its intelligent hot gas control, we use much less hot gas to defrost than our other freezers and we avoid having to place the freezer in que system,” said Tobias Janson, technical manager at HKScan Sweden. The company can now defrost up to three freezers at a time, enabling quicker turnaround and water and energy savings.

Learn more about the sustainable solutions we provide for our customers.